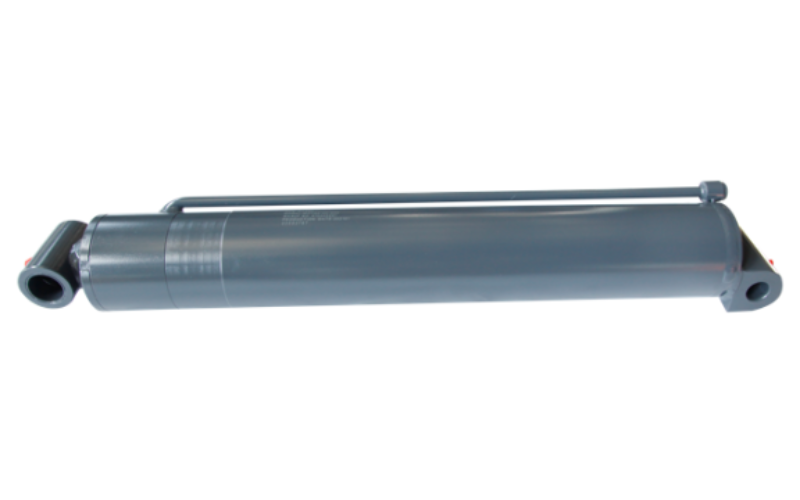

WCT WELDED CYLINDERS WITH CROSS TUBE MOUNTS

Detailed Drawing

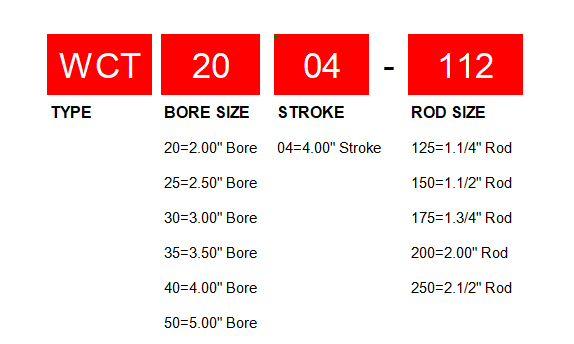

Model Code System

WCT Hydraulic Cylinder

The WCT Hydraulic Cylinders Model Code System is a comprehensive system of codes used to identify and specify the various components and specifications of hydraulic cylinders.

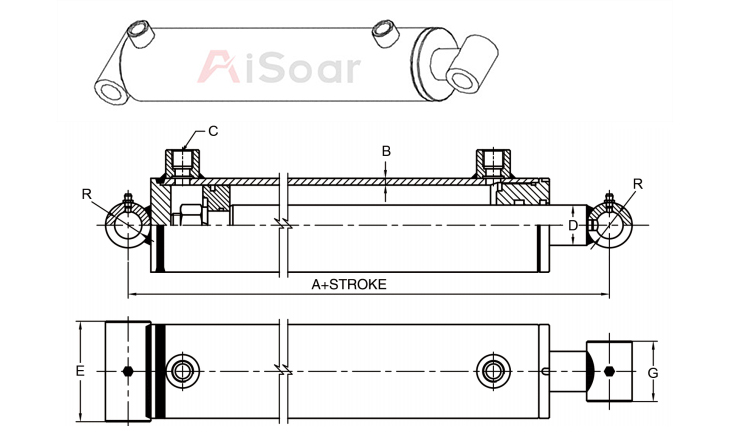

WCT Hydraulic Cylinder Drawing

We can check the main sizes in below drawing

| Dimensional Data in Inches (Miimeters) | |||||||

| BORE | A | B | C | D | E | G | R |

| 1.50 (38.10) | 8 (203.2) | 0.25 (6.35) | 1/4NPT | 1.00 (25.40) | 2.25 (57.15) | 2.00 (50.80) | 0.77 (19.56) |

| 2.00 (50.80) | 8 (203.2) | 0.25 (6.35) | 3/8NPT | 1.25 (31.75) | 2.75 (69.85) | 2.25 (57.15) | 1.02 (25.90) |

| 2.50 (63.50) | 8 (203.2) | 0.25 (6.35) | 3/8NPT | 1.50 (38.10) | 3.25 (82.55) | 2.25 (57.15) | 1.02 (25.90) |

| 3.00 (76.20) | 8 (203.2) | 0.25 (6.35) | 1/2NPT | 1.50 (38.10) | 3.75 (95.25) | 2.25 (57.15) | 1.02 (25.90) |

| 3.50 (88.90) | 10 (254) | 0.25 (6.35) | 1/2NPT | 1.75 (44.45) | 4.25 (107.95) | 2.25 (57.15) | 1.27 (32.26) |

| 4.00 (101.60) | 10 (254) | 0.25 (6.35) | 1/2NPT | 2.00 (50.80) | 4.75 (120.65) | 2.50 (63.50) | 1.52 (38.61) |

| 5.00 (127.00) | 12 (304.8) | 0.25 (6.35) | 1/2NPT | 2.50 (63.50) | 5.75 (146.05) | 3.25 (82.55) | 1.77 (44.96) |

Data Table

Here we can see importants dimensional datas for WCT cylinders

| ARTICLE | BORE INCH | STROKE INCH | ROD DIA INCH | LENGTH MIN INCH | LENGTH MAX INCH | PORT | WEIGHT LBS | WEIGHT KG |

| WCT1504-100 | 1.5 | 4 | 1 | 12 | 16 | 1/4NPT | 9.04 | 4.1 |

| WCT1506-100 | 1.5 | 6 | 1 | 14 | 20 | 1/4NPT | 10.14 | 4.6 |

| WCT1508-100 | 1.5 | 8 | 1 | 16 | 24 | 1/4NPT | 11.47 | 5.2 |

| WCT1510-100 | 1.5 | 10 | 1 | 18 | 28 | 1/4NPT | 12.79 | 5.8 |

| WCT2008-125 | 2 | 8 | 1.1/4 | 16 | 24 | 3/8NPT | 13.45 | 6.1 |

| WCT2010-125 | 2 | 10 | 1.1/4 | 18 | 28 | 3/8NPT | 15.21 | 6.9 |

| WCT2012-125 | 2 | 12 | 1.1/4 | 20 | 32 | 3/8NPT | 16.98 | 7.7 |

| WCT2014-125 | 2 | 14 | 1.1/4 | 22 | 36 | 3/8NPT | 18.74 | 8.5 |

| WCT2016-125 | 2 | 16 | 1.1/4 | 24 | 40 | 3/8NPT | 20.51 | 9.3 |

| WCT2018-125 | 2 | 18 | 1.1/4 | 26 | 44 | 3/8NPT | 22.27 | 10.1 |

| WCT2020-125 | 2 | 20 | 1.1/4 | 28 | 48 | 3/8NPT | 24.03 | 10.9 |

| WCT2024-125 | 2 | 24 | 1.1/4 | 32.8 | 56 | 3/8NPT | 27 | 12.2 |

| WCT2028-125 | 2 | 28 | 1.1/4 | 36 | 64 | 3/8NPT | 31.09 | 14.1 |

| WCT2030-125 | 2 | 30 | 1.1/4 | 38 | 68 | 3/8NPT | 32.85 | 14.9 |

| WCT2032-125 | 2 | 32 | 1.1/4 | 40 | 72 | 3/8NPT | 34.84 | 15.8 |

| WCT2036-125 | 2 | 36 | 1.1/4 | 44 | 80 | 3/8NPT | 38.37 | 17.4 |

| WCT2040-125 | 2 | 40 | 1.1/4 | 48 | 88 | 3/8NPT | 41.9 | 19 |

| WCT2048-125 | 2 | 48 | 1.1/4 | 56 | 104 | 3/8NPT | 48.95 | 22.2 |

| WCT2508-150 | 2.5 | 8 | 1.1/2 | 16 | 24 | 3/8NPT | 19.85 | 9 |

| WCT2510-150 | 2.5 | 10 | 1.1/2 | 18 | 28 | 3/8NPT | 21.83 | 9.9 |

| WCT2512-150 | 2.5 | 12 | 1.1/2 | 20 | 32 | 3/8NPT | 24.03 | 10.9 |

| WCT2514-150 | 2.5 | 14 | 1.1/2 | 22 | 36 | 3/8NPT | 26.24 | 11.9 |

| WCT2516-150 | 2.5 | 16 | 1.1/2 | 24 | 40 | 3/8NPT | 28.44 | 12.9 |

| WCT2518-150 | 2.5 | 18 | 1.1/2 | 26 | 44 | 3/8NPT | 30.65 | 13.9 |

| WCT2520-150 | 2.5 | 20 | 1.1/2 | 28 | 48 | 3/8NPT | 32.85 | 14.9 |

| WCT2524-150 | 2.5 | 24 | 1.1/2 | 32 | 56 | 3/8NPT | 37.26 | 16.9 |

| WCT2528-150 | 2.5 | 28 | 1.1/2 | 36 | 64 | 3/8NPT | 41.45 | 18.8 |

| WCT2530-150 | 2.5 | 30 | 1.1/2 | 38 | 68 | 3/8NPT | 43.66 | 19.8 |

| WCT2532-150 | 2.5 | 32 | 1.1/2 | 40 | 72 | 3/8NPT | 45.86 | 20.8 |

| WCT2536-150 | 2.5 | 36 | 1.1/2 | 44 | 80 | 3/8NPT | 50.27 | 22.8 |

| WCT2540-150 | 2.5 | 40 | 1.1/2 | 48 | 88 | 3/8NPT | 54.68 | 24.8 |

| WCT2548-150 | 2.5 | 48 | 1.1/2 | 56 | 104 | 3/8NPT | 63.28 | 28.7 |

| WCT3008-150 | 3 | 8 | 1.1/2 | 16 | 24 | 1/2NPT | 24.7 | 11.2 |

| WCT3010-150 | 3 | 10 | 1.1/2 | 18 | 28 | 1/2NPT | 27.12 | 12.3 |

| WCT3012-150 | 3 | 12 | 1.1/2 | 20 | 32 | 1/2NPT | 29.55 | 13.4 |

| WCT 3014-150 | 3 | 14 | 1.1/2 | 22 | 36 | 1/2NPT | 31.97 | 14.5 |

| WCT 3016-150 | 3 | 16 | 1.1/2 | 24 | 40 | 1/2NPT | 34.4 | 15.6 |

| WCT 3018-150 | 3 | 18 | 1.112 | 26 | 44 | 1/2NPT | 36.82 | 16.7 |

| WCT 3020-150 | 3 | 20 | 1.1/2 | 28 | 48 | 1/2NPT | 39.25 | 17.8 |

| WCT 3024-150 | 3 | 24 | 1.1/2 | 32 | 56 | 1/2NPT | 44.1 | 20 |

| WCT 3028-150 | 3 | 28 | 1.1/2 | 36 | 64 | 1/2NPT | 48.95 | 22.2 |

| WCT 3030-150 | 3 | 30 | 1.1/2 | 38 | 68 | 1/2NPT | 51.38 | 23.3 |

| WCT 3032-150 | 3 | 32 | 1.1/2 | 40 | 72 | 1/2NPT | 53.58 | 24.3 |

| WCT 3036-150 | 3 | 36 | 1.1/2 | 44 | 80 | 1/2NPT | 58.43 | 26.5 |

| WCT 3040-150 | 3 | 40 | 1.1/2 | 48 | 88 | 1/2NPT | 63.28 | 28.7 |

| WCT 3048-150 | 3 | 48 | 1.1/2 | 56 | 104 | 1/2NPT | 72.99 | 33.1 |

| WCT 3508-175 | 3.5 | 8 | 1.3/4 | 18 | 26 | 1/2NPT | 32.63 | 14.8 |

| WCT 3510-175 | 3.5 | 10 | 1.3/4 | 20 | 30 | 1/2NPT | 35.72 | 16.2 |

| WCT 3512-175 | 3.5 | 12 | 1.3/4 | 22 | 34 | 1/2NPT | 38.81 | 17.6 |

| WCT 3514-175 | 3.5 | 14 | 1.3/4 | 24 | 38 | 1/2NPT | 41.67 | 18.9 |

| WCT 3516-175 | 3.5 | 16 | 1.3/4 | 26 | 42 | 1/2NPT | 44.76 | 20.3 |

| WCT 3518-175 | 3.5 | 18 | 1.3/4 | 28 | 46 | 1/2NPT | 47.63 | 21.6 |

| WCT 3520-175 | 3.5 | 20 | 1.3/4 | 30 | 50 | 1/2NPT | 50.72 | 23 |

| WCT 3524-175 | 3.5 | 24 | 1.3/4 | 34 | 58 | 1/2NPT | 56.67 | 25.7 |

| WCT 3528-175 | 3.5 | 28 | 1.3/4 | 38 | 66 | 1/2NPT | 62.62 | 28.4 |

| WCT 3530-175 | 3.5 | 30 | 1.3/4 | 40 | 70 | 1/2NPT | 65.71 | 29.8 |

| WCT 3532-175 | 3.5 | 32 | 1.3/4 | 42 | 74 | 1/2NPT | 68.8 | 31.2 |

| WCT 3536-175 | 3.5 | 36 | 1.3/4 | 46 | 82 | 1/2NPT | 74.75 | 33.9 |

| WCT 3540-175 | 3.5 | 40 | 1.3/4 | 50 | 90 | 1/2NPT | 80.7 | 36.6 |

| WCT 3548-175 | 3.5 | 48 | 1.3/4 | 58 | 106 | 1/2NPT | 92.61 | 42 |

| WCT 4008-200 | 4 | 8 | 2 | 18 | 26 | 1/2NPT | 40.79 | 18.5 |

| WCT 4010-200 | 4 | 10 | 2 | 20 | 30 | 1/2NPT | 44.54 | 20.2 |

| WCT 4012-200 | 4 | 12 | 2 | 22 | 34 | 1/2NPT | 48.29 | 21.9 |

| WCT 4014-200 | 4 | 14 | 2 | 24 | 38 | 1/2NPT | 51.82 | 23.5 |

| WCT 4016-200 | 4 | 16 | 2 | 26 | 42 | 1/2NPT | 55.57 | 25.2 |

| WCT 4018-200 | 4 | 18 | 2 | 28 | 46 | 1/2NPT | 59.09 | 26.8 |

| WCT 4020-200 | 4 | 20 | 2 | 30 | 50 | 1/2NPT | 62.84 | 28.5 |

| WCT 4024-200 | 4 | 24 | 2 | 34 | 58 | 1/2NPT | 70.12 | 31.8 |

| WCT 4028-200 | 4 | 28 | 2 | 38 | 66 | 1/2NPT | 77.4 | 35.1 |

| WCT 4030-200 | 4 | 30 | 2 | 40 | 70 | 1/2NPT | 81.14 | 36.8 |

| WCT 4032-200 | 4 | 32 | 2 | 42 | 74 | 1/2NPT | 84.67 | 38.4 |

| WCT 4036-200 | 4 | 36 | 2 | 46 | 82 | 1/2NPT | 91.95 | 41.7 |

| WCT 4040-200 | 4 | 40 | 2 | 50 | 90 | 1/2NPT | 99.23 | 45 |

| WCT 4048-200 | 4 | 48 | 2 | 58 | 106 | 1/2NPT | 114 | 51.7 |

| WCT 5008-250 | 5 | 8 | 2.1/2 | 20 | 28 | 1/2NPT | 71.88 | 32.6 |

| WCT 5010-250 | 5 | 10 | 2.1/2 | 22 | 32 | 1/2NPT | 76.07 | 34.5 |

| WCT 5012-250 | 5 | 12 | 2.1/2 | 24 | 36 | 1/2NPT | 80.48 | 36.47 |

| WCT 5014-250 | 5 | 14 | 2.1/2 | 26 | 40 | 1/2NPT | 84.67 | 38.37 |

| WCT 5016-250 | 5 | 16 | 2.1/2 | 28 | 44 | 1/2NPT | 89.08 | 40.37 |

| WCT 5018-250 | 5 | 18 | 2.1/2 | 30 | 48 | 1/2NPT | 93.49 | 43.37 |

| WCT 5020-250 | 5 | 20 | 2.1/2 | 32 | 52 | 1/2NPT | 97.68 | 44.27 |

| WCT 5024-250 | 5 | 24 | 2.1/2 | 36 | 60 | 1/2NPT | 106.28 | 48.17 |

| WCT 5028-250 | 5 | 28 | 2.1/2 | 40 | 68 | 1/2NPT | 115.1 | 52.16 |

| WCT 5030-250 | 5 | 30 | 2.1/2 | 42 | 72 | 1/2NPT | 119.29 | 54.06 |

| WCT 5032-250 | 5 | 32 | 2.1/2 | 44 | 76 | 1/2NPT | 123.7 | 56.06 |

| WCT 5036-250 | 5 | 36 | 2.1/2 | 48 | 84 | 1/2NPT | 132.3 | 59.96 |

| WCT 5040-250 | 5 | 40 | 2.1/2 | 52 | 92 | 1/2NPT | 140.9 | 63.86 |

| WCT 5048-250 | 5 | 48 | 2.1/2 | 60 | 108 | 1/2NPT | 158.1 | 71.65 |

Get Your WCT Hydraulic Cylinders Today!

Call us or visit our website to get more information about the hydraulic cylinders you need.

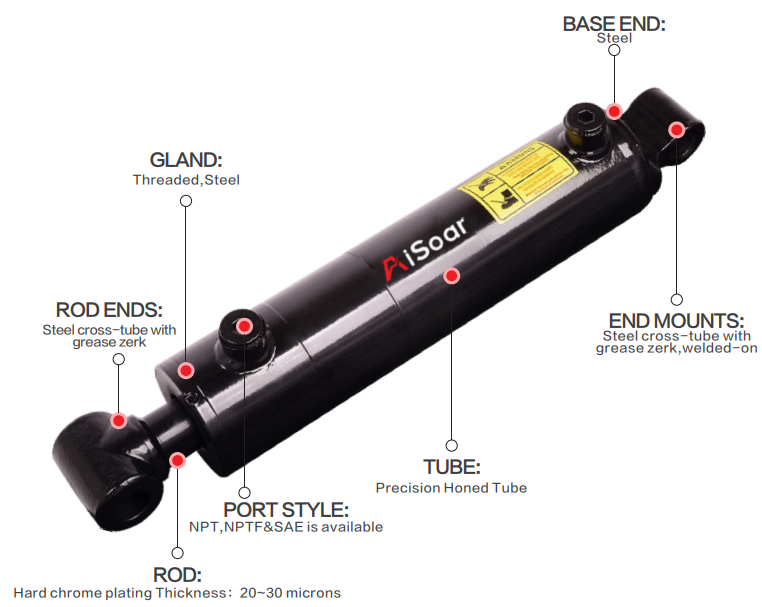

Material

We Always Use Good Quality Material For Our WCT Cylinders

- ROD:Hard chrome plating Thickness:20~30 microns.

- TUBE:Steel tube honed or skived for extended seal life.

- GLAND:Steel.

- PISTON:Steel.

- END MOUNTS:Steel cross-tube with grease zerk, welded-on.

- PORTS:NPT, NPTF&SAE is optional.

- SEALS:Hallite.

- PAINT:Black(STD), color and other custom colors are available.

- ROD ENDS:Steel cross-tube with grease zerk

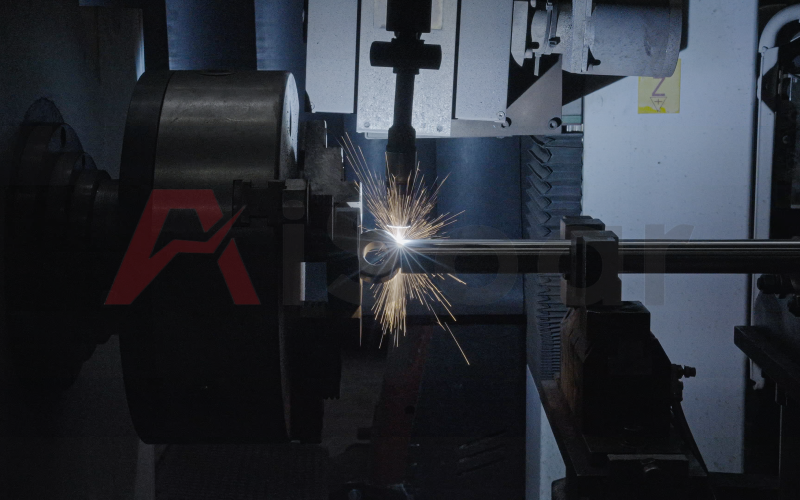

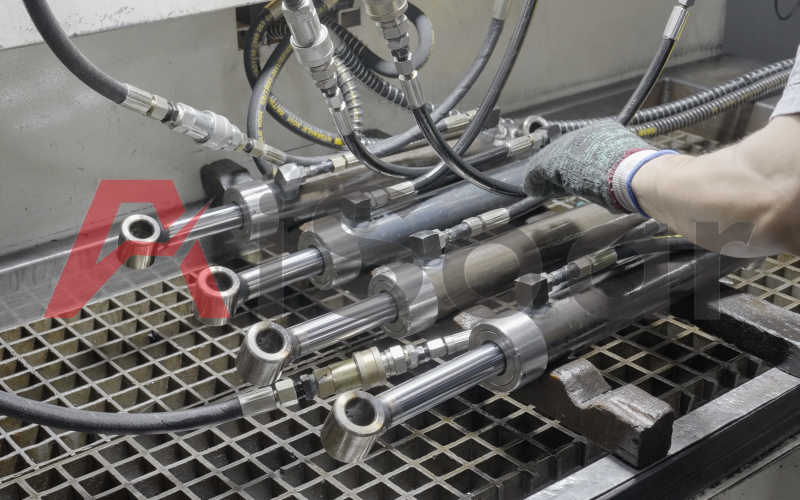

Production Processes

How We Produce WCT Hydraulic Cylinders

Our Factory

Our Factory

OEM Custom Service is Available

What Kind Of Cylinders Do You Need?

There are a handful of different types of cylinders for different industries, but no matter which type you need, even custom welded hydraulic cylinders, AiSoar can provide them.

Cross-Tube Welded Hydrulic Cylinder With Intergrated Valve

Integrated within the cylinder is a hydraulic valve, which regulates the flow of fluid into and out of the cylinder chambers. This valve plays a crucial role in controlling the speed, direction, and force of the cylinder's movement, enabling precise positioning and operation of machinery or equipment. Common types of hydraulic valves include directional control valves, pressure control valves, and flow control valves, each serving specific functions in the hydraulic system.

The cross tube hydraulic cylinder with a valve offers several advantages in hydraulic applications. Firstly, the integrated valve simplifies the hydraulic circuitry, reducing the need for additional components and minimizing potential leak points. This streamlined design enhances reliability and efficiency while facilitating easier installation and maintenance procedures.

(Single-Acting Hydraulic Cylinder with Customized Port Style)

The cross tube design enhances the cylinder's structural integrity, making it robust and suitable for heavy-duty applications. Customized port styles offer flexibility in configuring inlet and outlet ports according to the unique needs of the hydraulic system.

Customization of port styles involves tailoring the placement, orientation, and sizing of ports to optimize fluid flow, minimize hose routing complexity, and ensure compatibility with existing plumbing configurations. Engineers strategically position ports to reduce interference with surrounding components and enhance system efficiency.

Furthermore, customization extends to the selection of port types and sizes, such as SAE straight-thread ports, NPT ports, or metric ports, to ensure seamless integration with other system components. Precisely matched port dimensions minimize the risk of leaks and pressure losses, enhancing overall system performance and reliability.

FAQ

Frequently Asked Questions

We'll try to answer some of your questions

A: Yes, we have Tang cylinders for this purpose.

You can confidently utilize equipment with AiSoar hydraulics year after year for four reasons:

1. AiSoar Hydraulics provides value pricing without sacrificing quality. When implementing rigid quality standards and controlling raw materials, the key to cost control for us is standard and large-scale production.

2. We take care of our cylinders as if they were our children. Before assembly, we clean all the parts with a high-pressure cleaning machine, and we flush before testing. Each cylinder would go through the testing procedure before packaging to make sure there was no internal or external seal leakage. Paint with primer first before the main paint to make sure the cylinders look perfect.

3. Short-run production for customized cylinders, even just at 1 pc, is fully supported.

4. We have launched a 3D Drawing Gallery, where you can get access to 3D drawings for WCT cylinders.

Determine the bore and stroke size of your cylinder, and you’re ready to go. AiSoar Hydraulics is here to serve you.

A:Firstly, you should choose the bore size, rod size, stroke, working pressure, required force (Column Load).

Secondly, check the drawings' sizes carefully, especially the mounting sizes, include the min. distance of clevis, and etc.

A:Rigid quality standards & control on raw materialsare always implemented in AiSoar hydraulics. We have really stable suppliers with long-term cooperative relationship. We inspection for each batch of incoming goods, and review our supplier quality performance by year.

Aisoar Hydraulic Cylinders Catalogue

AiSoar hydraulics offers WCT series of welded hydraulic cylinders with cross tube mounted both rod ends and cap, available in a variety of bore and stroke sizes. As a standard type, cylinders' bore sizes up to 4 inches, strokes up to 48 inches with pressure ratings up to 3000PSI. For WCT series cylinders, non-standard options are available, such as customized stroke, integrated valve and stainless steel tube/rod. Single acting is optional, too.

Download

Get a Quote Now

ANYTHING YOU COULDN'T FIND?

Talk with one of our sales representatives

Hydraulic Cylinder Manufacturer? Contact Immediately For Consultation.

Send us an email

Contact Us

Have any question about our AiSoar Hydraulic?Please contact us and we will get back to you immediately.

ES

ES RU

RU