Brand Story

Brand Story

1999

In 1999, Mr. Ying, the founder, was living in a small town in southeastern China, working in a Chinese state-owned enterprise as a director of technical department, when he learned that the local purchase price of hydraulic cylinders is very expensive, but the quality is not so good, so he decided to build a hydraulic cylinder factory. As a result, a small workshop was rented, where high-quality hydraulic cylinders were designed and manufactured.

2016

In 2016, a modern factory was built with 100 employees. ISO9001 Quality Management System and MES System are applied to ensure quality, which means that we are quite capable of providing standard and custom hydraulic cylinders, hydraulic power units because we have a team of experienced engineers consisting of more than 10 engineers, including hydraulic engineers, electrical engineers, and mechanical engineers.

2020

In 2020, a new company was established by Ms. Ying in a modern city, Hangzhou, in order to develop international business and technology, attracting more excellent talents, making hydraulic cylinder products of better quality, providing more professional services, inspiring our Ardor with Innovation, Soar the world together with you!

OUR COMPANY

Professional Hydraulic Cylinder

AiSoar Hydraulic is a professional manufacturer and supplier of hydraulic cylinders, hydraulic power pack units, hydraulic testing machines and hydraulic components. AiSoar Hydraulics is located in Hangzhou city of Zhejiang Province, near to Shanghai and Ningbo Port.

Today, AiSoar Hydraulics has 130 long term contracted workers specialized in hydraulics, and our monthly production of hydraulic cylinders capacity is over 30,000 pcs. Our products are mostly exported to Europe and North America.

Our factory covers an area of 13,000 square meters with modern-standard workshops and cutting-edge equipment. The 6S and ERP management systems are rigidly implemented throughout our whole company. Our factory is an ISO9001 and CE certified manufacturer.

As a family-owned business effortlessly operated by two diligent generations, we value our business and our hydraulics like our children. We are serious about our cylinders, and we take customers' needs seriously. We are willing to grow with all partners, and to support partners in every possible way we can to survive it together

Our Capabilities

-

Standard Hydraulic Cylinder

AiSoar Hydraulics offers supplies standard hydraulic cylinder ,widely used in agricultural industry. We manufacture and stock a range of welded hydraulics cylinders, tie rod cylinders. We have many choices of rod and end mounts.

-

OEM Customized Hydraulic Cylinder

AiSoar Hydraulics is a manufacturer of engineered hydraulic cylinders. We are also an approved supplier to many large OEM equipment manufacturers in the mobile industry. we offer high quality products at very affordable pricing. We offer a competitive warranty, be assured, we stand by our product.

-

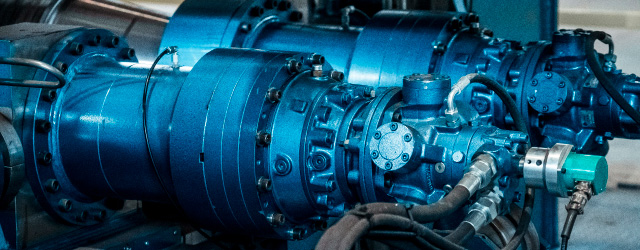

Hydraulic System

AiSoar Hydraulic systems are built with the focus on quality. We have professional engineers to ensure that our hydraulic systems are powerful and reliable. We have many options for you to consider, hydraulic systems are completely customizable to suit your application requirements.

-

Hydraulic Testing Machine

AiSoar Hydraulics manufactures high quality and durable hydraulic testing machine as customers' specific requirements. Our skilled hydraulic engineers and electrical engineers would like to work together with you to make your own hydraulic testing machine.

-

Hydraulic Components

AiSoar Hydraulics is not only a hydraulic cylinder manufacturer, and we also offer other hydraulic components such as hydraulic motors, gear pumps, and more. We hope to be your trusted source for your hydraulic requirements.

Get The Hydraulic

Cylinder

Aisoar hydraulics has earned great reputations for superior quality and high performance. Aisoar hydraulics have been widely used in agricultural equipment, construction equipment, trailers, excavators and other fields.

Sales & Service

In the sales department, we do our best to meet customers' specific requirements. We know hydraulics, and we know how to help our customers build their own hydraulic cylinders and hydraulic systems. We mostly quote within 24 hours. The MOQ for hydraulic cylinders and hydraulic systems is one piece. Small and mid-size batch orders for customized cylinders are fully supported. All customers' profiles and requirements are carefully documented through the ERP system to help track all aspects of each order and provide tailored services.

Technical Service

Our engineers come across as easy to communicate with, efficient, and experienced in our R&D Department and Engineering Department. Our customers’ were impressed by their professionalism. We launched 3D drawings for 15 series hydraulic cylinders; you can access our website to get them or ask us to provide them to you. A PLM system is implemented to process CAD, 3D drawings, and technical data. We are quite capable of designing and building the complete hydraulic system per the customers’ specific requirements because we have skilled hydraulic engineers and electrical engineers.

Sourcing Department

In the Sourcing Department, stable raw material suppliers are regularly selected and inspected to keep the cost down and assure quality. We source the best materials from trusted suppliers. Implementing rigid quality standards and control on raw materials, each batch of incoming materials shall be inspected according to strict sampling schemes.

Production

Our production department is quite strong and powerful, with good management means, advanced equipment, good manufacturing technique, and workers with over a decade of experience as well. Our production capacity of hydraulic cylinders is over 30,000 pieces to meet customers' batch orders. In the Production Department, Lean Production Management and the MES system are adopted. We have more than 200 sets of processing equipment, including 30 sets of Mazac and Dawei turning and milling compound centers, etc. With advanced equipment and techniques, the quality of our hydraulic products is assured. Moreover, 84% of workers have more than 5–10 years of experience in the mechanical industry.

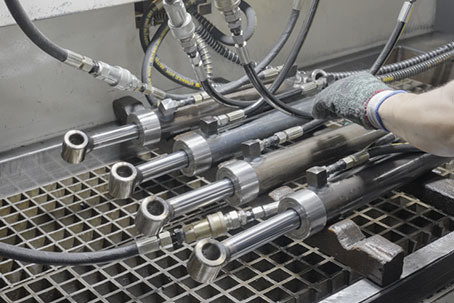

Quality

The QC Department is equipped with precision instruments and machinery, standard process management, 100% testing capacity, and traceability. A full range of testing instruments. Monitoring of testing equipment at regular intervals. Implementing whole-process quality inspection Incoming goods and outgoing goods shall be inspected according to sampling schemes. Outgoing goods shall be 100% gone through the test procedure.

HOW TO PRODUCT

Production Process Control

Saw Cutting Machine

CNC Machine

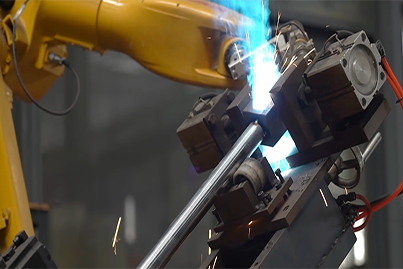

Welding

Washing Machine

Assembly & Test

Painting

HOW TO INSPECT

Whole Process Quality

Laboratory with Advanced Testing Instruments

Laboratory with Advanced Testing Instruments

Salt Spraying Tester

Sclerometer

Plating Thickness Tester

Cleanliness Tester

CMM

Altimeter

Ultrasonic Testing

Pressure Testing Machine

Paint Film Thickness Detector

Cross-cut Test

HOW TO STORAGE &SHIPPING

Storage & Shipping

Our standard package is bubble bag + wooden box, it is safety. We also accept custom package if needed.

We have reliable shipping agent which enable us to keep the competitive shipping cost and quick shipping time. If you have your own shipping agent, pls let us know in advance, thank you.

OUR SERVICE

What Type of Welded Cylinder Do You Have?

There are a handful of different types of cylinders for different industries, but no matter which type you need, even custom welded hydraulic cylinders, AiSoar can provide them.

Hydraulic Severe-Duty Welded Cylinders

Hydraulic severe-duty welded cylinders can withstand a whopping 5,000 pound force per square inch of pressure, and have larger bore sizes and increased wall tubing, making them the ideal choice for more extreme mill applications.

Hydraulic Severe-Duty Welded Cylinders

Hydraulic severe-duty welded cylinders can withstand a whopping 5,000 pound force per square inch of pressure, and have larger bore sizes and increased wall tubing, making them the ideal choice for more extreme mill applications.

20 YEARS IN BUSINESS

Solutions For Your Cylinders

We can supply a wide range of hydraulic cylinders, including tie rod cylinders, welded cylinders, single-acting cylinders, and double-acting cylinders. Moreover, we can also customize hydraulic cylinders to meet customers' requirements on mounting styles, pressure ratings, sizes, and configurations.

Explore More

ES

ES RU

RU