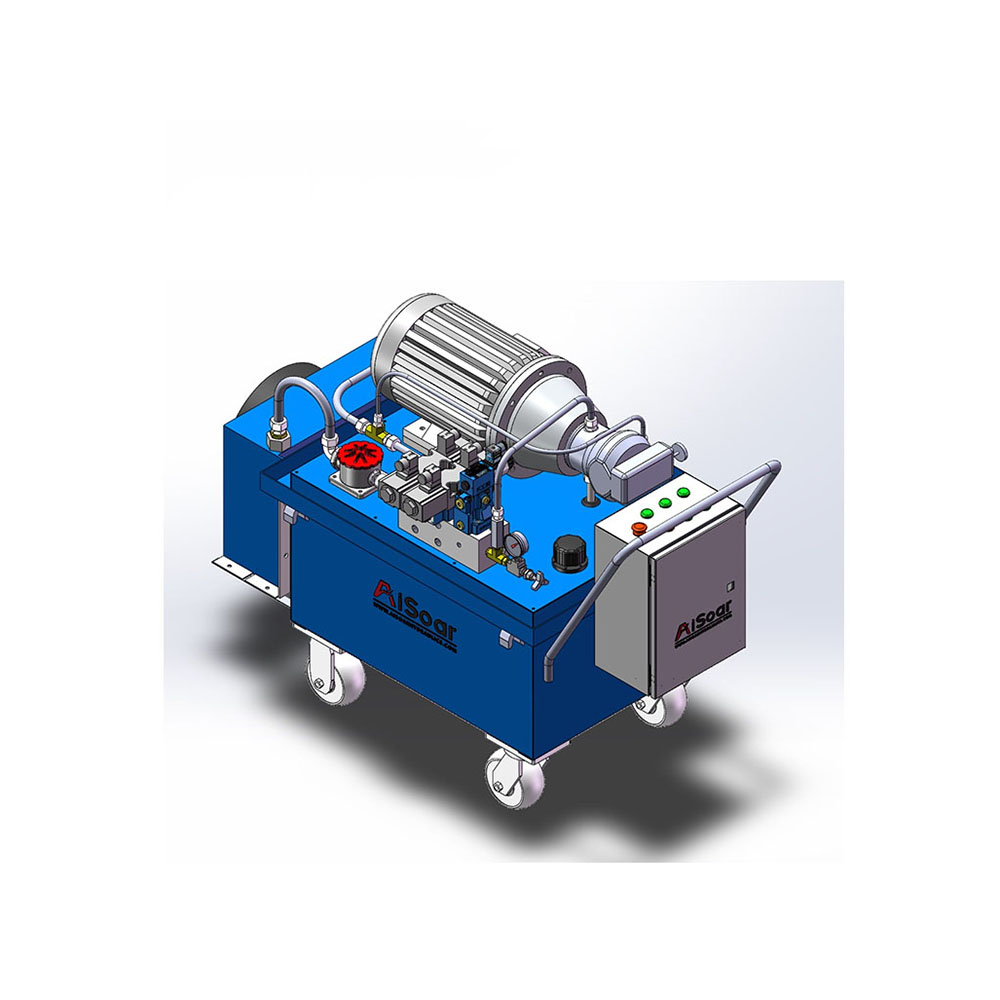

Hydraulic Testing Machine

AiSoar hydraulics design and manufacture high quality and durable hydraulic testing machine as customers' specific requirements. We have standard hydraulic testers for you choice, and we are quite capable of designing and making customized hydrualic testing bench together with our customers as well. Our skilled hydraulic engineers and electrical engineers would like to work together with you to make your own hydraulic testing machine.

China Hydraulic Test Bench Manufacturers and Suppliers

AiSoar Hydraulics provides standard hydraulic testing machines and customized hydraulic test benches to meet customers' specific r

OEM Hydraulic Testing Machine

AiSoar Hydraulics provides hydraulic testing machines, such as hydraulic cylinder testers. This hydraulic testing machine is quite

High Quality Hydraulic Cylinder Tester

The hydraulic tester is quite useful for the manufacture of hydraulic products or the supplier of hydraulic maintenance. For the m

Hydraulic Cylinder Testing Machine Manufacturer And Supplier In China

Hydraulic cylinder testing machine was called as hydrualic tester or testing bench, it's job is including but not limited to using it to test the performance of hydraulic cylinder.

AISOAR hydraulics as a testing machine manufacturer and supplier in China, we provides standard hydraulic testing machine and customized hydraulic testing machine to meet customers' specific requirements, we have lots of succesful experience as well. The hydraulic testing machine is quite useful for the manufacture of hydraulic products or the supplier of hydraulic maintenance.

The hydraulic testing machine is quite useful for the manufacture of hydraulic products or the supplier of hydraulic maintenance. For the manufactures, before the hydraulic products deliver to customers, we have to guarantee they are prefect without seal leaks, they have gone through the test procedure by the testing machine, this testing step is essential. For supplier of hydraulic maintenance, we have to prove that each hydraulic products’ repair is perfect before reinstalled, each parts have been well repaired, the testing has become a necessary step before deliver them to user. With 3000 PSI testing capacity, all cylinder repairs can be guaranteed not to fail when reinstalled into the field. The hydraulic products will work prefect, means greater profit, satisfied customers and long term customer loyalty.

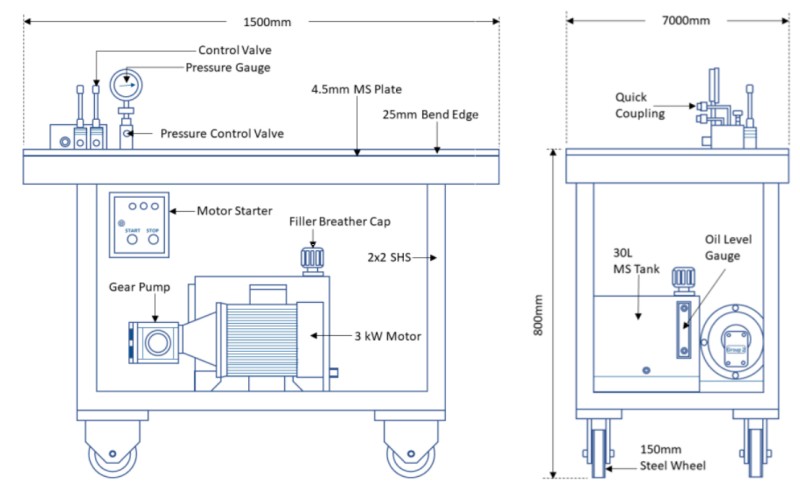

The Features and Benifits of Hydraulic Test Bench

| Robust Power Supply |

Powered by an advanced hydraulic power unit, our bench ensures consistent, high-performance testing with variable pressure and flow controls. |

| Accurate Monitoring | Equipped with premium pressure gauges, flow meters, and temperature sensors, it delivers precise measurements for comprehensive analysis. |

| Safety First Design | Incorporating essential safety features, it provides a secure testing environment, safeguarding operators and equipment. |

|

Muti-Fuctional Testing Capabilities: |

Ideal for a wide range of hydraulic components like valves, hoses, and cylinders, catering to diverse industrial needs. |

| Enhanced Performance Analysis | Identify potential issues with pinpoint accuracy, ensuring your hydraulic systems meet the highest standards of efficiency and reliability. |

| Time and Cost-Efficient | Streamline your testing processes, reducing downtime and maintenance costs with early detection of faults. |

|

Customizable Testing Scenarios |

Simulate real-world conditions with adjustable settings, tailoring tests to specific operational requirements. |

The Function of Hydraulic Testing Bench

Internal leaks are easy to find

Detecting actuator leaks and evaluating cylinder condition (i.e. scoring, seals and packing) is a safe and straighforward process with the Hydraulic Test Bench:

• Cylinders/actuators are tested for leaks at maximum stroke.

• Pressure reducing valves and pressure relief valves can be tested individually.

Pre-setting / inspection of valves

Accurate valve adjustments/settings can be performed before being fixed into the hydraulic circuit.

Reduce the risk and improve safety

Hydraulic testing machine allows you to inspect the hydraulic component and identify any malfunctioning individually. This helps avoid the risk and act before it's too late.

Minimize the cost and maximize performance with an improved life cycle

The HTB is designed to prevent the high costs of repairs and maintenance, ultimately allowing you to spend your money wisely. Eventually, proper monitoring and care of hydraulic components will help improve reliability and spreader life cycle

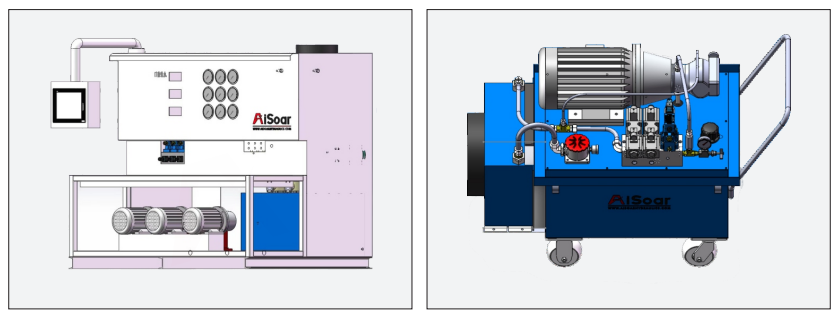

The Different Types of Hydraulic Test Bench

(1) Performance test bench: this allows the hydraulic performance of a product to be measured and adjusted. Hydraulic performance test benches are used to verify or define the maximum technical use characteristics of a product according to various criteria: flow rate, pressure, temperature, tightness, sensitivity, etc.

(2) Endurance test bench, also called fatigue test bench: it is used to check the life and reliability characteristics of a product. The number of test cycles can reach several million (flow rate, pressure, temperature) under variable atmospheric and climatic conditions.

(3) Control bench, or "validation bench": it verifies and validates the technical characteristics of a product during the production phase. The test bench makes it possible to check that the product's performance meets the design specifications before it is marketed.

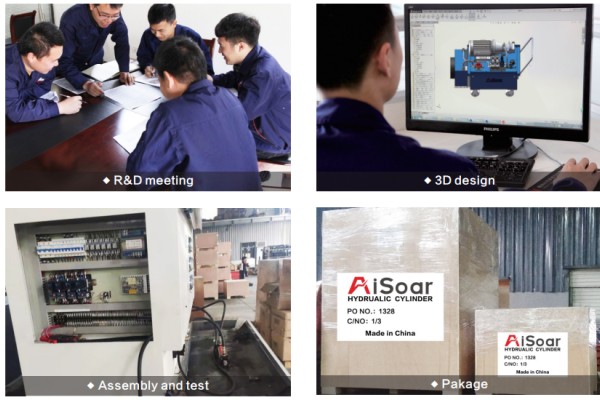

The Process of making a hydraulic testing machine

① At Sales Department, all customers’profiles and requirements are carefully documented through ERP system, to help track all aspects of each orders, and to provide tailored services.

② At our R&D Department and Engineering Department, PLM system is implemented to process CAD, 3D drawings and technical data.

③ At Sourcing Department, stable raw material suppliers are regularly selected and inspected, to keep the cost down and to assure the quality.

④ In the Production Department, Lean Production Management and MES system are adapted. With advanced equipment and techniques, quality is assured.

⑤ The QC Department are equipped with precision instrument and machinery, standard process management, 100% testing capacity and trace-ability.

Opt for the AiSoar Hydraulic Testing Bench that combines precision, versatility, and safety. Ensure the optimum performance of your hydraulic systems with our reliable and advanced testing solution!

ES

ES RU

RU