Hydraulic Cylinder Test Method

Our hydraulic cylinders are used in agricultural equipment, trailers, garbage trucks, construction machinery and other fields. We pay attention to the quality of hydraulic cylinders and inspect each hydraulic cylinder. Do you know how to test hydraulic cylinders? Now let me introduce to you how we test hydraulic cylinders.

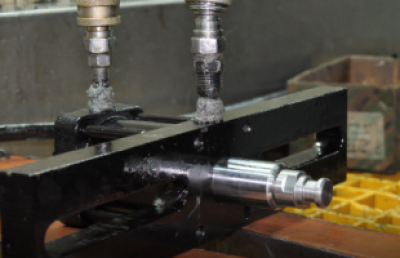

Trial operation of hydraulic cylinder:

The hydraulic cylinders of each station are in place, the hydraulic cylinders to be tested are connected, the ball valve is opened, the oil pump is started, the conditions of each key part are checked, the electro-hydraulic reversing valve is operated to change the direction, and the hydraulic cylinder starts pre-operation.

Starting pressure of hydraulic cylinder:

Pre-connect the pressure gauge to the working chamber to be tested, and manually visually inspect the digital display electronic pressure gauge. After operating the electro-hydraulic directional valve to change direction, slowly adjust the control handle of the overflow valve until the hydraulic cylinder starts to start, then observe and record the pressure The pressure value on the table. Run 2-3 cycles for exhaust, and the number of cycles can be adjusted. It is mainly to observe whether the cylinder has long-stroke crawling, severe jitter, and whether the short-stroke hydraulic cylinder is stuck in parallel operation and other abnormal conditions.

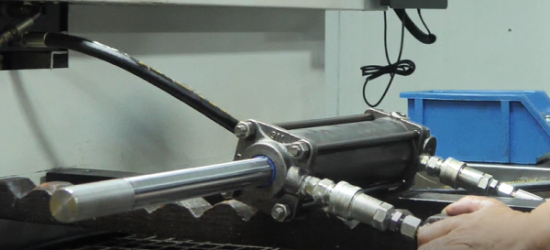

Pressure test of hydraulic cylinder:

The pressure test also includes a static pressure holding test. After the tested hydraulic cylinder reaches the end of its stroke, the medium and high pressure are automatically switched, and the ultra-high pressure pump automatically continues to pressurize the working chamber. The pressure is smoothly and effectively supplied through the pre-adjusted relief valve. Oil, at this time, keep the position of the electro-hydraulic valve reversing, and let the high-pressure plunger pump continue to pressurize for 1-2 minutes (the pressure is 1.25 or 1.5 times the working pressure).

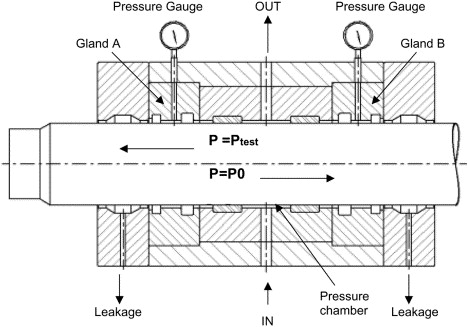

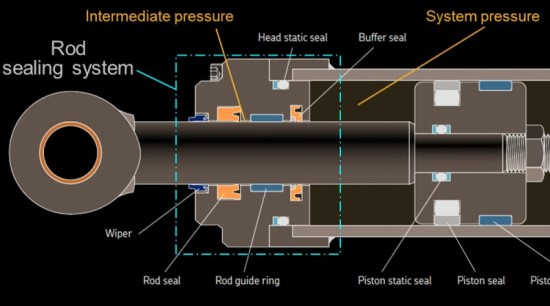

Leakage test of hydraulic cylinder:

1). External leakage: During the first, second, and third tests, check the welding points on the outside of the hydraulic cylinder, the piston rod and the guide sleeve, the guide sleeve and the cylinder liner, the joints and flange connections on the cylinder block, etc. Whether there is leakage or leakage at the seal.

2). Internal leakage: The test method focuses on the third item (pressure holding test in the pressure test): it must be combined with the pressure test, that is, after the continuous pressure stops, the high-pressure system is unloaded and the hydraulic oil is directly returned to the tank. The hydraulic control check valve automatically locks the oil circuit, and the hydraulic cylinder oil cavity maintains pressure. After confirming that there is no leakage in the system oil circuit of the test bench or the natural leakage value of the system, check the pressure drop per unit time for indirect feedback. Eligibility should be based on the actual situation of the site to formulate standards.

Hydraulic cylinder buffer test:

Observe the cushioning effect when the hydraulic cylinder reaches the two ends, adjust the cushion throttle rod of the cylinder, watch the change of the cushioning speed, manually monitor the impact of the piston and the cylinder end cover, and analyze whether the product needs to be adjusted to be qualified.

Hydraulic stroke detection test:

During the above-mentioned test process of the hydraulic cylinder on the test bench, the effective extension length (longest and shortest) of the piston rod can be measured manually or mechanically during the static pressure holding period. At this time, the result is recorded and compared with the original design data. , To find out whether the stroke of the hydraulic cylinder meets the regulations, and at the same time, the speed of the stroke of the hydraulic cylinder under a certain flow rate can be calculated, and the maximum accuracy per unit time can reach 1mm/sec.

Drain the oil after the hydraulic cylinder test:

1) After the hydraulic cylinder test is completed, the qualified product records the data in turn, and the unqualified product manually compares the test results of each link, makes necessary processing, corrects the data or retests.

2) After the test, the hydraulic cylinder must be drained and reset regardless of whether it is qualified or not. After confirming that there is no high pressure after the pressure is released from the hydraulic cylinder, manually switch the hydraulic cylinder oil discharge control button. At this time, no matter where the piston rod of the tested hydraulic cylinder is, it will be moved back and forth several times without load. After confirming that the hydraulic oil in the cylinder is basically drained, the piston rod is reduced to the shortest dimension, and the hydraulic cylinder test is ended.

This test may result in cylinder failure or personal injury. Always wear appropriate personal protective equipment. If you have any further questions about hydraulic cylinders, please contact email: alice@ai-soar.com or contact us.

|

AISOAR HYDRAULIC CYLINDERS |

ES

ES RU

RU