WCC WELDED CYLINDER WITH CLEVIS MOUNTS

Detailed Drawing

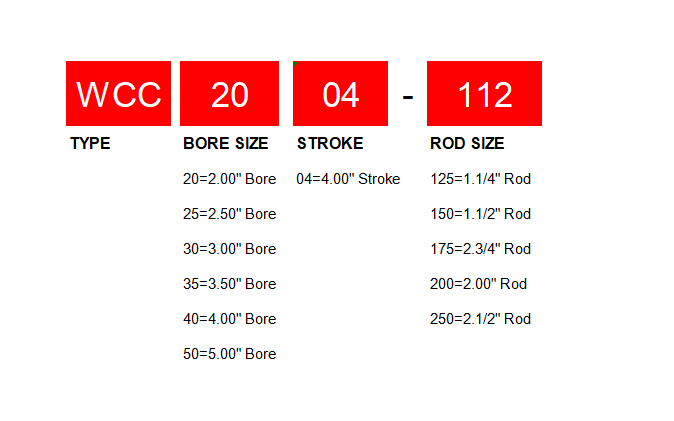

Model Code System

WCC Hydraulic Cylinder

The welded clevis hydraulic cylinders are robust and efficient components used in heavy-duty applications. They feature a welded barrel design with a clevis end, allowing for easy mounting. These cylinders are known for their strength and durability, ideal for high-pressure environments. Their design simplifies maintenance and enhances reliability, making them suitable for various industries, including construction, agriculture, and manufacturing. Welded clevis hydraulic cylinders are customizable in size and specifications to meet specific operational needs.

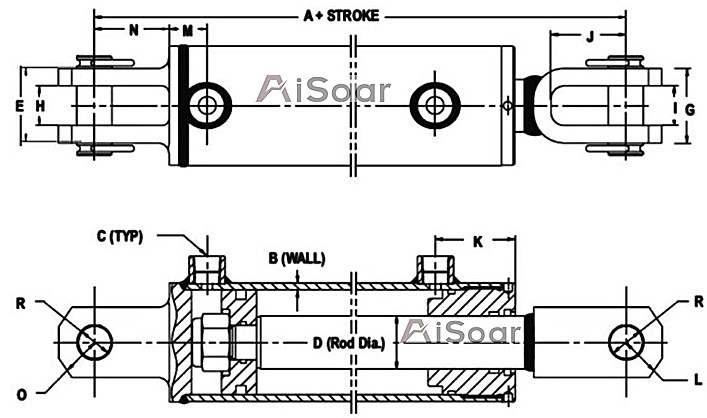

WCC Hydraulic Cylinder Drawing

We can check the main sizes in below drawing

| DIMENSIONAL DATA IN INCHES(MILIMETERS) | |||||||||||||||

| BORE | A | B | C | D | E | G | H | I | J | K | L | M | N | O | R |

| 2.000 (50.8) | 10.25 (260.35) | 0.25 (6.35) | 3/8NPT | 1.25 (31.75) | 2.48 (63) | 2.48 (63) | 1.125 (28.57) | 1.125 (28.57) | 2.125 (53.9) | 2.008 (51) | 1.26 (32) | 1.535 (39) | 2.125 (53.9) | 1.26 (32) | 1.012 (25.7) |

| 2.500 (63.5) | 10.25 (260.35) | 0.25 (6.35) | 3/8NPT | 1.5 (38.1) | 2.48 (63) | 2.48 (63) | 1.125 (28.57) | 1.125 (28.57) | 2.125 (53.9) | 2.008 (51) | 1.26 (32) | 1.535 (39) | 2.125 (53.9) | 1.26 (32) | 1.012 (25.7) |

| 3.000 (76.2) | 10.25 (260.35) | 0.25 (6.35) | 1/2NPT | 1.5 (38.1) | 2.48 (63) | 2.48 (63) | 1.125 (28.57) | 1.125 (28.57) | 2.125 (53.9) | 2.008 (51) | 1.26 (32) | 1.535 (39) | 2.125 (53.9) | 1.26 (32) | 1.012 (25.7) |

| 3.500 (88.9) | 10.25 (260.35) | 0.25 (6.35) | 1/2NPT | 1.75 (44.45) | 2.48 (63) | 2.48 (63) | 1.125 (28.57) | 1.125 (28.57) | 2.244 (57) | 2.008 (51) | 1.377 (35) | 1.535 (39) | 2.047 (52) | 1.378 (35) | 1.012 (25.7) |

| 4.000 (101.6) | 10.25 (260.35) | 0.25 (6.35) | 1/2NPT | 2 (50.8) | 2.48 (63) | 2.48 (63) | 1.125 (28.57) | 1.125 (28.57) | 2.244 (57) | 2.283 (58) | 1.377 (35) | 1.102 (28) | 2.047 (52) | 1.378 (35) | 1.012 (25.7) |

Data Table

Here we can see importants dimensional datas for WCC cylinders

| ARTICLE | BORE INCH | STROKE INCH | ROD DIAINCH | LENGTH MIN LENGTH | LENGTH MAX LENGTH | RETRAP INDIA | PORT | WEIGH TLBS | WEIGHT KG |

| WCC2004-125 | 2 | 4 | 1.1/4 | 14.25 | 18.25 | 1 | 3/8NPT | 12.79 | 5.8 |

| WCC2006-125 | 2 | 6 | 1.1/4 | 16.25 | 22.25 | 1 | 3/8NPT | 14.55 | 6.6 |

| WCC2008-125 | 2 | 8 | 1.1/4 | 18.25 | 26.25 | 1 | 3/8NPT | 16.32 | 7.4 |

| WCC2010-125 | 2 | 10 | 1.1/4 | 20.25 | 30.25 | 1 | 3/8NPT | 17.86 | 8.1 |

| WCC2012-125 | 2 | 12 | 1.1/4 | 22.25 | 34.25 | 1 | 3/8NPT | 19.4 | 8.8 |

| WCC2014-125 | 2 | 14 | 1.1/4 | 24.25 | 38.25 | 1 | 3/8NPT | 21.17 | 9.6 |

| WCC2016-125 | 2 | 16 | 1.1/4 | 26.25 | 42.25 | 1 | 3/8NPT | 22.93 | 10.4 |

| WCC2018-125 | 2 | 18 | 1.1/4 | 28.25 | 46.25 | 1 | 3/8NPT | 24.48 | 11.1 |

| WCC2020-125 | 2 | 20 | 1.1/4 | 30.25 | 50.25 | 1 | 3/8NPT | 26.24 | 11.9 |

| WCC2024-125 | 2 | 24 | 1.1/4 | 34.25 | 58.25 | 1 | 3/8NPT | 29.55 | 13.4 |

| WCC2028-125 | 2 | 28 | 1.1/4 | 38.25 | 66.25 | 1 | 3/8NPT | 32.85 | 14.9 |

| WCC2030-125 | 2 | 30 | 1.1/4 | 40.25 | 70.25 | 1 | 3/8NPT | 34.62 | 15.7 |

| WCC2032-125 | 2 | 32 | 1.1/4 | 42.25 | 74.25 | 1 | 3/8NPT | 36.16 | 16.4 |

| WCC2034-125 | 2 | 34 | 1.1/4 | 44.25 | 78.25 | 1 | 3/8NPT | 37.93 | 17.2 |

| WCC2036-125 | 2 | 36 | 1.1/4 | 46.25 | 82.25 | 1 | 3/8NPT | 36.69 | 16.6 |

| WCC2504-150 | 2.5 | 4 | 1.1/2 | 14.25 | 18.25 | 1 | 1/2NPT | 16.98 | 7.7 |

| WCC2506-150 | 2.5 | 6 | 1.112 | 16.25 | 22.25 | 1 | 1/2NPT | 19.18 | 8.7 |

| WCC2508-150 | 2.5 | 8 | 1.1/2 | 18.25 | 28.25 | 1 | 1/2NPT | 21.39 | 9.7 |

| WCC2510-150 | 2.5 | 10 | 1.1/2 | 20.25 | 30.25 | 1 | 1/2NPT | 23.37 | 10.6 |

| WCC2512-150 | 2.5 | 12 | 1.1/2 | 22.25 | 34.25 | 1 | 1/2NPT | 25.58 | 11.6 |

| WCC3008-150 | 3 | 8 | 1.1/2 | 18.25 | 28.25 | 1 | 1/2NPT | 26.9 | 12.2 |

| WCC3010-150 | 3 | 10 | 1.1/2 | 20.25 | 30.25 | 1 | 1/2NPT | 29.11 | 13.2 |

| WCC3012-150 | 3 | 12 | 1.1/2 | 22.25 | 34.25 | 1 | 1/2NPT | 31.53 | 14.3 |

| WCC3014-150 | 3 | 14 | 1.1/2 | 24.25 | 38.25 | 1 | 1/2NPT | 33.96 | 15.4 |

| WCC3016-150 | 3 | 16 | 1.1/2 | 26.25 | 42.25 | 1 | 1/2NPT | 36.6 | 16.6 |

| WCC3018-150 | 3 | 18 | 1.1/2 | 28.25 | 46.25 | 1 | 1/2NPT | 39.03 | 17.7 |

| WCC3020-150 | 3 | 20 | 1.1/2 | 30.25 | 50.25 | 1 | 1/2NPT | 41.45 | 18.8 |

| WCC3024-150 | 3 | 24 | 1.1/2 | 34.25 | 58.25 | 1 | 1/2NPT | 46.31 | 21 |

| WCC3028-150 | 3 | 28 | 1.1/2 | 38.25 | 66.25 | 1 | 1/2NPT | 51.16 | 23.2 |

| WCC3030-150 | 3 | 30 | 1.1/2 | 40.25 | 70.25 | 1 | 1/2NPT | 53.58 | 24.3 |

| WCC3032-150 | 3 | 32 | 1.1/2 | 42.25 | 74.25 | 1 | 1/2NPT | 56.23 | 25.5 |

| WCC3034-150 | 3 | 34 | 1.1/2 | 44.25 | 78.25 | 1 | 1/2NPT | 58.65 | 26.6 |

| WCC3036-150 | 3 | 36 | 1.1/2 | 46.25 | 82.25 | 1 | 1/2NPT | 61.08 | 27.7 |

| WCC3504-175 | 3.5 | 4 | 1.3/4 | 14.25 | 18.25 | 1 | 1/2NPT | 26.24 | 11.9 |

| WCC3506-175 | 3.5 | 6 | 1.3/4 | 16.25 | 22.25 | 1 | 1/2NPT | 29.33 | 13.3 |

| WCC3508-175 | 3.5 | 8 | 1.3/4 | 18.25 | 28.25 | 1 | 1/2NPT | 32.41 | 14.7 |

| WCC3510-175 | 3.5 | 10 | 1.3/4 | 20.25 | 30.25 | 1 | 1/2NPT | 35.5 | 16.1 |

| WCC3512-175 | 3.5 | 12 | 1.3/4 | 22.25 | 34.25 | 1 | 1/2NPT | 38.59 | 17.5 |

| WCC3514-175 | 3.5 | 14 | 1.3/4 | 24.25 | 38.25 | 1 | 1/2NPT | 41.67 | 18.9 |

| WCC3516-175 | 3.5 | 16 | 1.3/4 | 26.25 | 42.25 | 1 | 1/2NPT | 44.76 | 20.3 |

| WCC3518-175 | 3.5 | 18 | 1.3/4 | 28.25 | 46.25 | 1 | 1/2NPT | 48.07 | 21.8 |

| WCC3520-175 | 3.5 | 20 | 1.3/4 | 30.25 | 50.25 | 1 | 1/2NPT | 51.16 | 23.2 |

| WCC3524-175 | 3.5 | 24 | 1.3/4 | 34.25 | 58.25 | 1 | 1/2NPT | 57.33 | 26 |

| WCC3528-175 | 3.5 | 28 | 1.3/4 | 38.25 | 66.25 | 1 | 1/2NPT | 63.5 | 28.8 |

| WCC3530-175 | 3.5 | 30 | 1.3/4 | 40.25 | 70.25 | 1 | 1/2NPT | 66.59 | 30.2 |

| WCC3532-175 | 3.5 | 32 | 1.3/4 | 42.25 | 74.25 | 1 | 1/2NPT | 69.9 | 31.7 |

| WCC3534-175 | 3.5 | 34 | 1.3/4 | 44.25 | 78.25 | 1 | 1/2NPT | 72.99 | 33.1 |

| WCC3536-175 | 3.5 | 36 | 1.3/4 | 46.25 | 82.25 | 1 | 1/2NPT | 76.07 | 34.5 |

| WCC4004-200 | 4 | 4 | 2 | 14.25 | 18.25 | 1 | 1/2NPT | 30.65 | 13.9 |

| WCC4006-200 | 4 | 6 | 2 | 16.25 | 22.25 | 1 | 1/2NPT | 34.4 | 15.6 |

| WCC4008-200 | 4 | 8 | 2 | 18.25 | 28.25 | 1 | 1/2NPT | 39.25 | 17.8 |

| WCC4010-200 | 4 | 10 | 2 | 20.25 | 30.25 | 1 | 1/2NPT | 42.12 | 19.1 |

| WCC4012-200 | 4 | 12 | 2 | 22.25 | 34.25 | 1 | 1/2NPT | 46.08 | 20.9 |

| WCC4014-200 | 4 | 14 | 2 | 24.25 | 38.25 | 1 | 1/2NPT | 50.05 | 22.7 |

| WCC4016-200 | 4 | 16 | 2 | 26.25 | 42.25 | 1 | 1/2NPT | 53.8 | 24.4 |

| WCC4018-200 | 4 | 18 | 2 | 28.25 | 46.25 | 1 | 1/2NPT | 57.77 | 26.2 |

| WCC4020-200 | 4 | 20 | 2 | 30.25 | 50.25 | 1 | 1/2NPT | 61.52 | 27.9 |

| WCC4024-200 | 4 | 24 | 2 | 34.25 | 58.25 | 1 | 1/2NPT | 69.46 | 31.5 |

| WCC4028-200 | 4 | 28 | 2 | 38.25 | 66.25 | 1 | 1/2NPT | 77.18 | 35 |

| WCC4030-200 | 4 | 30 | 2 | 40.25 | 70.25 | 1 | 1/2NPT | 81.14 | 36.8 |

| WCC4032-200 | 4 | 32 | 2 | 42.25 | 74.25 | 1 | 1/2NPT | 84.89 | 38.5 |

| WCC4034-200 | 4 | 34 | 2 | 44.25 | 78.25 | 1 | 1/2NPT | 88.86 | 40.3 |

| WCC4036-200 | 4 | 36 | 2 | 46.25 | 82.25 | 1 | 1/2NPT | 92.61 | 42 |

| WCC5006-250 | 5 | 6 | 2.1/2 | 18.25 | 24.25 | 1 | 1/2NPT | 68.36 | 31 |

| WCC5008-250 | 5 | 8 | 2.1/2 | 20.25 | 28.25 | 1 | 1/2NPT | 72.77 | 33 |

| WCC5010-250 | 5 | 10 | 2.1/2 | 22.25 | 32.25 | 1 | 1/2NPT | 77.18 | 35 |

| WCC5012-250 | 5 | 12 | 2.1/2 | 24.25 | 36.25 | 1 | 1/2NPT | 81.59 | 37 |

Get Your WCC WELDED CYLINDER WITH CLEVIS MOUNTS Today!

Call us or visit our website to get more information about the hydraulic cylinders you need.

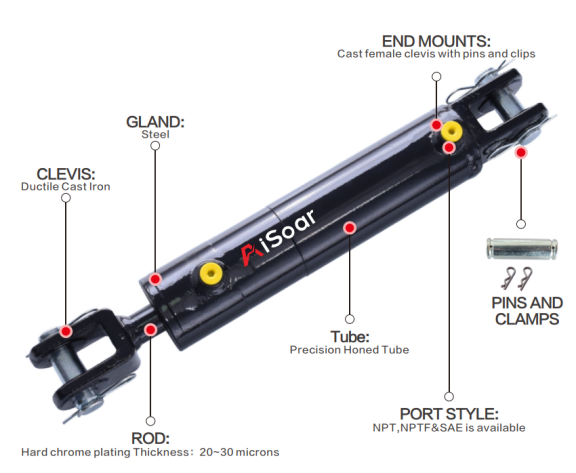

Material

We Always Use Good Quality Material For Our WCC Cylinders

- ROD:Hard chrome plated.

- TUBE:Precision honed steel for extended seal life.

- GLAND:Steel.

- PISTON:Steel.

- END MOUNTS:Steel cast female clevises with pins and clips included

- PORTS:NPT,NPTF&SAE is available.

- SEALS:Hallite.

- PAINT:Black(STD), color and other custom colors are available.

- ROD ENDS:Steel cast female clevises with pins and clips included.

Production Processes

How We Produce WCC Hydraulic Cylinders

Our Factory

Our Factory

OEM Custom Service is Available

What Kind Of Cylinders Do You Need?

There are a handful of different types of cylinders for different industries, but no matter which type you need, even custom welded hydraulic cylinders, AiSoar can provide them.

ODM/OEM oders are welcome for us

Customized port styles are fully supported by the AiSoar, and we have several options for you.

Customized clevis sizes are available and completely meet your specific requirements for a specific application

(Welded Clevis Hydraulic Cylinders Integrated With Counterbalance Valve)

WCC series welded clevis cylinders are the standard type of cylinders, but customized strokes, intergraded valves, and special tube or rod material is optional.

FAQ

Frequently Asked Questions

We'll try to answer some of your questions

A: Yes, closed length from center pin to center pin, we also call out retracted length or min. length. Open length is the retracted on centers plus the stroke, we also call out extended length or max. length.

A: Measured in between pin hole centers. We would like to show you videos via WhatsApp or Wechat.

A: Technically yes, however it depends on the type of log splitter you have. You need to see the type of attachment on your splitter and advice the bore size and stroke.

A: It's a good question. TR2008 and WCC2008, same bore size, same stroke, same retracted length, same pin size, similar clevis. You can see the difference as below pictures. There are two oil ports on cap of TR serial, and only one oil port on cap of WCC serial. The shape size of WCC serial is smaller, as it no needs to be welded tie rods.

You can confidently utilize equipment with AiSoar hydraulics year after year for four reasons:

1. AiSoar Hydraulics provides value without sacrificing quality. When implementing rigid quality standards and controlling raw materials, the key to cost control for us is standard and large-scale production.

2. We take care of our cylinders like our children. Before assembly, we clean all the parts through a high-pressure cleaning machine, and we flush before testing. Each cylinder would go through the testing procedure before packaging to make sure there was no internal or external seal leakage. Painted with primer first before the main paint to make sure the cylinders look perfect.

3. Short-run production for customized cylinders, even just at 1 pc, is fully supported.

4. We have launched a 3D Drawing Gallery, where you can get access to 3D drawings for WCC cylinders.

A:Reasonable and stable Price, stable and consistent quality, and good service. For more than 20 years, AiSoar hydraulics has earned great reputations for superior quality and high performance. Our factory covers an area of 13,000 square meters with modern-standard workshops and cutting edge equipment. With over 30,000 pcs of production capacity each month, with the overall scale effect, raw material costs can be at their lowest, production efficiency is at its highest level, and labor costs are better controlled.

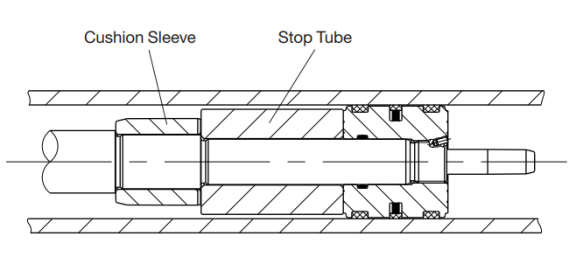

A: Optional stop tubes design for some applications. A stop tube with required length should be used to extend the min. distance of cylinders. Note that net strokes equal to the gross stroke of the cylinder less the length of the stop tube. The gross stroke determines the enveloped dimensions of the cylinder. A stop tube with required length should be used to reduce bearing stress for long stroke cylinders under compressive loads.

Aisoar Hydraulic Cylinders Catalogue

The WCC cylinders with clevis mounted both rod ends and base ends, we call out TR series. AiSoar tie rod cylinders, available in a variety of bore and stroke sizes, bore size ranges from 2 to 5 inches, stroke ranges from 4 to 48 inches, working pressure ranges from 2500PSI to 3000PSI.

DownloadGet a Quote Now

ANYTHING YOU COULDN'T FIND?

Talk with one of our sales representatives

Hydraulic Cylinder Manufacturer? Contact Immediately For Consultation.

Send us an email

Contact Us

Have any question about our AiSoar Hydraulic?Please contact us and we will get back to you immediately.

ES

ES RU

RU