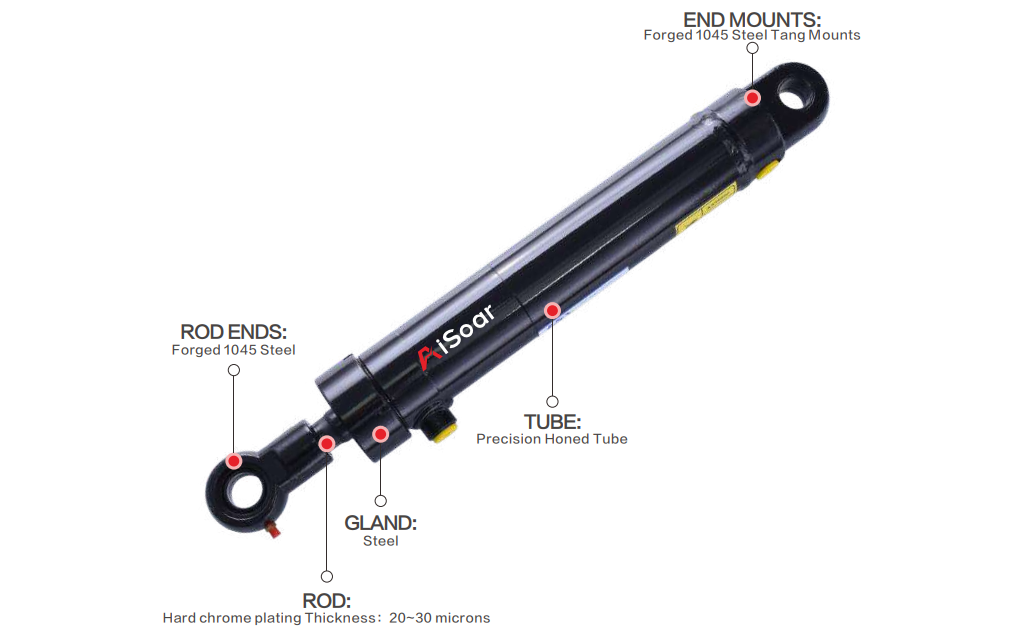

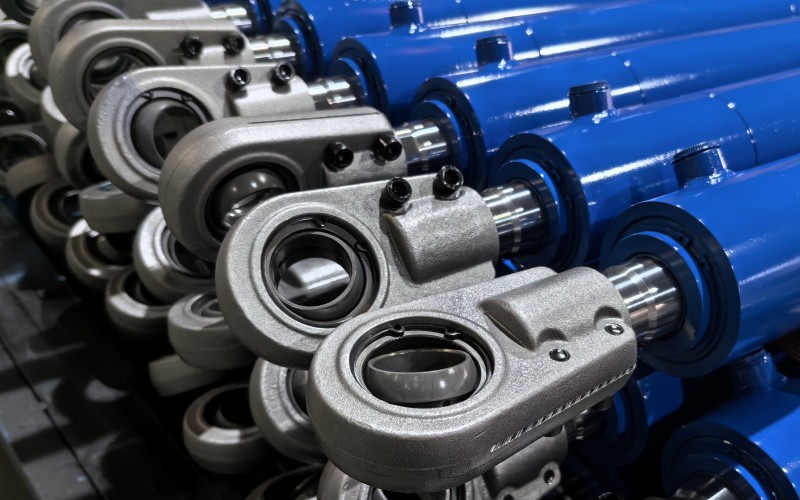

WTG WELDED CYLINDER WITH TANG MOUNTS

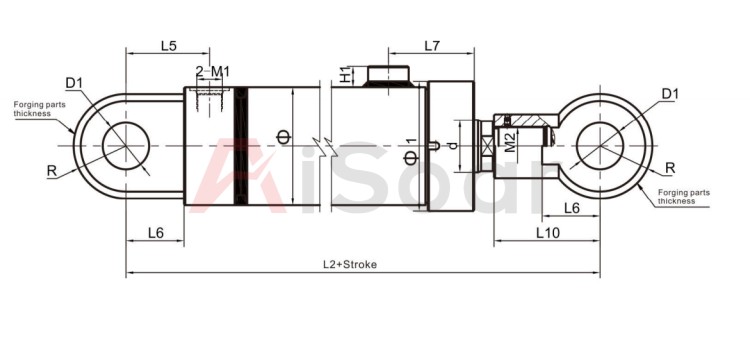

Detailed Drawing

Model Code System

WTG Hydraulic Cylinder

AiSoar Hydraulics specifically manufactured the tang hydraulic cylinders in order to give customers more options than only the industry-standard stock cylinders. The tang ends can fit into limited frames, and the ports were made to line up with pin holes. These exclusive products possess solid chrome plating, welded mounting ends, and premium-quality steel construction.

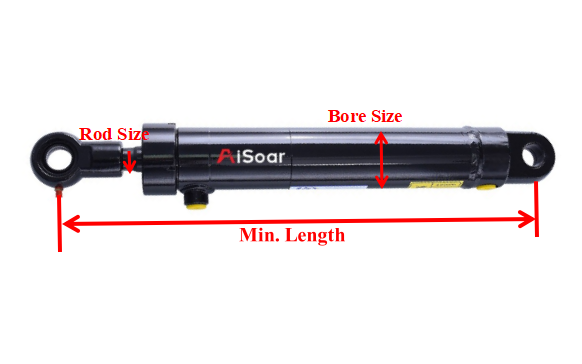

WTG Hydraulic Cylinder Drawing

We can check the main sizes in below drawing

| Bore | φ | d | D1 | R/b | L6 | M2 | L10 | L5★ | L7★ | L2 | 2-M1 | H1 | φ1 | ||

| DΨ=1.33 | DΨ=1.46 | DΨ=2 | |||||||||||||

| φ40 | 55 | 20 | 22 | 25 | 20 or GE20ES | 25 | 30 | M18×2 | 65 | 47 | 55 | 270 | M14×1.5 | 15 | 65 |

| φ50 | 65 | 25 | 28 | 32 | 30 or GE30ES | 35 | 40 | M24×2 | 75 | 57 | 55 | 295 | M18×1.5 | 18 | 75 |

| φ63 | 80 | 32 | 35 | 45 | 30 or GE30ES | 35 | 40 | M24×2 | 75 | 60 | 65 | 305 | M18×1.5 | 18 | 90 |

| φ80 | 100 | 40 | 45 | 55 | 40 or GE40ES | 45 | 50 | M39×3 | 105 | 72 | 60▲75 | 372 | M22×1.5 | 20 | 110 |

| φ90 | 114 | 45 | 50 | 63 | 40 or GE40ES | 45 | 50 | M39×3 | 105 | 72 | 60▲75 | 377 | M22×1.5 | 20 | — |

| φ100 | 125 | 50 | 55 | 70 | 50 or GE50ES | 60 | 65 | M50×3 | 135 | 89 | 60▲85 | 427 | M27×2 | 22 | — |

| φ110 | 140 | 55 | 63 | 80 | 50 or GE50ES | 60 | 65 | M50×3 | 135 | 91 | 65▲85 | 442 | M27×2 | 22 | — |

| φ125 | 152 | 63 | 70 | 90 | 50 or GE50ES | 60 | 65 | M50×3 | 135 | 91 | 65▲85 | 447 | M27×2 | 22 | — |

| φ140 | 166 | 70 | 80 | 100 | 60 or GE60ES | 70 | 75 | M64×3 | 170 | 105 | 70▲90 | 513 | M27×2 | 22 | — |

| φ150 | 178 | 80 | 90 | 110 | 60 or GE60ES | 70 | 75 | M64×3 | 170 | 110 | 70▲90 | 523 | M33×2 | 30 | — |

| φ160 | 194 | 80 | 90 | 110 | 60 or GE60ES | 70 | 75 | M64×3 | 170 | 110 | 75▲95 | 533 | M33×2 | 30 | — |

| φ180 | 219 | 90 | 100 | 125 | 70 or GE70ES | 80 | 85 | M80×3 | 195 | 125 | 75▲95 | 593 | M42×2 | 30 | — |

| φ200 | 245 | 100 | 110 | 140 | 80 or GE80ES | 90 | 95 | M90×3 | 210 | 135 | 79▲95 | 628 | M42×2 | 30 | — |

| φ220 | 273 | 110 | 125 | 160 | 90 or GE90ES | 100 | 105 | M100×3 | 250 | 145 | 85▲105 | 710 | M42×2 | 30 | — |

| φ250 | 125 | 125 | 170 | 180 | 100 or GE100ES | 110 | 120 | M110×4 | 275 | 160 | 90▲110 | 779 | M42×2 | 30 | — |

1. Ψ is the ratio of piston chamber effective area and piston rod chamber etfective area.

2. The maximum stroke: S=3D when 4=1.33 ; S=10D when y=1.46; S=12D when Ψ=2.

3."s1" means the minimum stroke expect for trunnion and intermediate flange mountings.

Data Table

Here we can see importants dimensional datas for WTG cylinders

Get Your WTG Hydraulic Cylinders Today!

Call us or visit our website to get more information about the hydraulic cylinders you need.

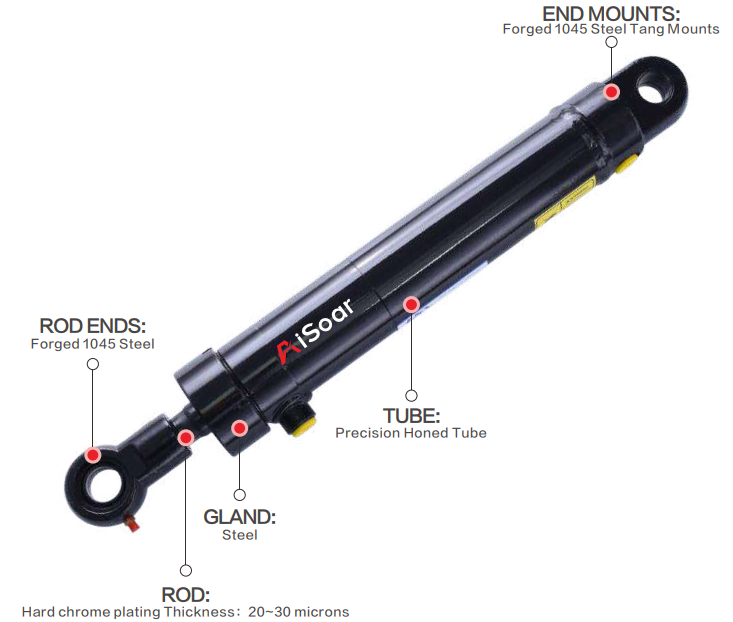

Material

We Always Use Good Quality Material For Our WTG Cylinders

- ROD:Hard chrome plated.

- TUBE:Precision honed steel for extended seal life.

- GLAND:Steel.

- PISTON:Steel.

- END MOUNTS:Forged 1045 Steel Tang Mounts.

- PORTS:SAE, NPT are available.

- SEALS:Hallite.

- PAINT:black, custom colors are available.

- ROD ENDS:Forged 1045 Steel.

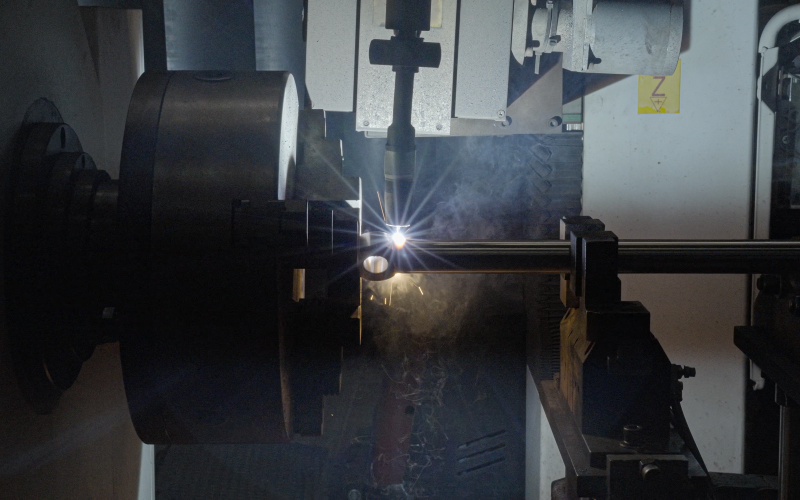

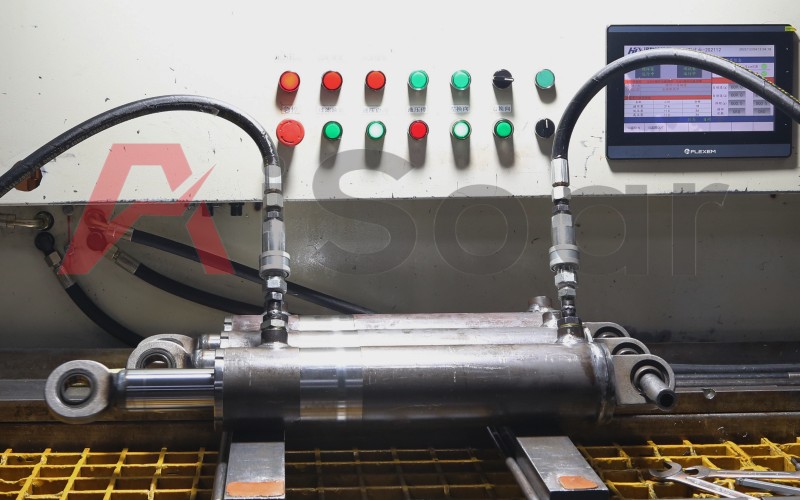

Production Processes

How We Produce WTG Hydraulic Cylinders

Our Factory

Our Factory

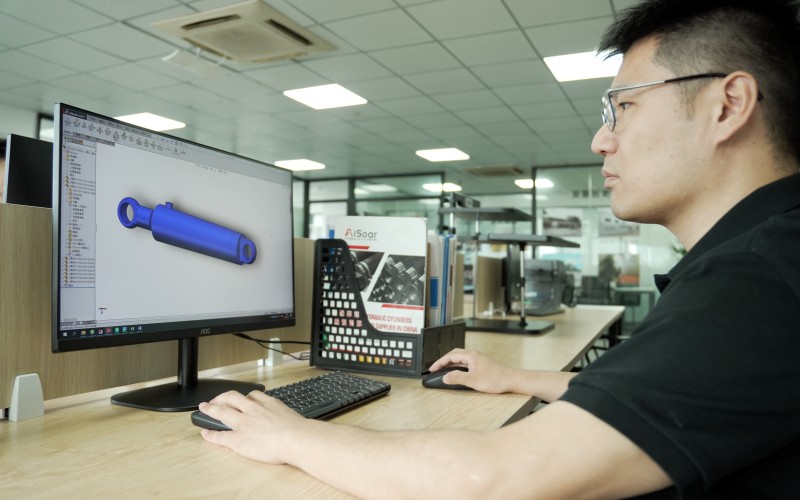

OEM Custom Service is Available

What Kind Of Cylinders Do You Need?

These cylinders come in a handful of different types and are used in different industries, but no matter which type you need , even custom welded hydraulic cylinders, AiSoar is able to provide them.

WTG WELDED CYLINDER WITH TANG MOUNTS GUIDE:

Step1: Requirement Analysis: Understand the specific needs of your application, including load capacity, stroke length, mounting requirements, and environmental conditions.

Step2: Design Parameters: Determine key design parameters, such as bore diameter, rod diameter, and overall dimensions, to meet your application's requirements.

Step3: Select Materials: Choose appropriate materials for the cylinder body, piston, rod, seals, and other components based on the operating environment and load conditions.

Step4: Mounting Options: Decide on the type of tang mount and its dimensions to ensure secure attachment to your equipment.

Step5: Customization: Incorporate any specific features or customization options needed for your application, such as position sensors, cushions, or special coatings.

Step6: Engineering and Modeling: Utilize CAD software to create detailed engineering drawings and 3D models of the custom cylinder.

AiSoar Displacement Sensor Hydraulic Cylinder

A Tang Mount Displacement Sensor Cylinder is a specialized hydraulic cylinder designed to provide accurate and real-time position feedback within a hydraulic system. This cylinder integrates a displacement sensor, such as a linear potentiometer or magnetostrictive sensor, directly into its structure.

As the hydraulic cylinder extends or retracts, the integrated displacement sensor measures the linear movement of the piston or rod inside the cylinder.This sensor generates a continuous signal that reflects the precise position of the cylinder at any given moment.The position feedback signal is transmitted to a control system or operator interface, allowing for real-time monitoring and control of the cylinder's position.

FAQ

Frequently Asked Questions

We'll try to answer some of your questions

A: Yes, we design and make customized hydrualic cylinder. Whatever do you prefer a complete customized hydrualic cylinder or slight modify base on the standard one, our engineer would like to fully support.

A: Yes, it's a rebuild-able cylinder and we do offer repair kits. Tie rod type is easy to repair.

A: 1" pin hole for bore size 1"~4", and 1.25" pin hole for bore size 5".

A: Definitely yes, we have our own factory. We would like to show you videos via WhatsApp or Wechat.

Aisoar Hydraulic Cylinders Catalogue

Aisoar hydraulics supplies Tang mounted cylinders, rod and base ends with one piece lug mount welded, insert a spherical or steel bushing to improve war life. Tang cylinders are most commonly used in heavy duty construction equipment.

DownloadGet a Quote Now

ANYTHING YOU COULDN'T FIND?

Talk with one of our sales representatives

Hydraulic Cylinder Manufacturer? Contact Immediately For Consultation.

Send us an email

Contact Us

Have any question about our AiSoar Hydraulic?Please contact us and we will get back to you immediately.

ES

ES RU

RU