TRACTOR HYDRAULIC TOP LINK WITH RAPID HOOK

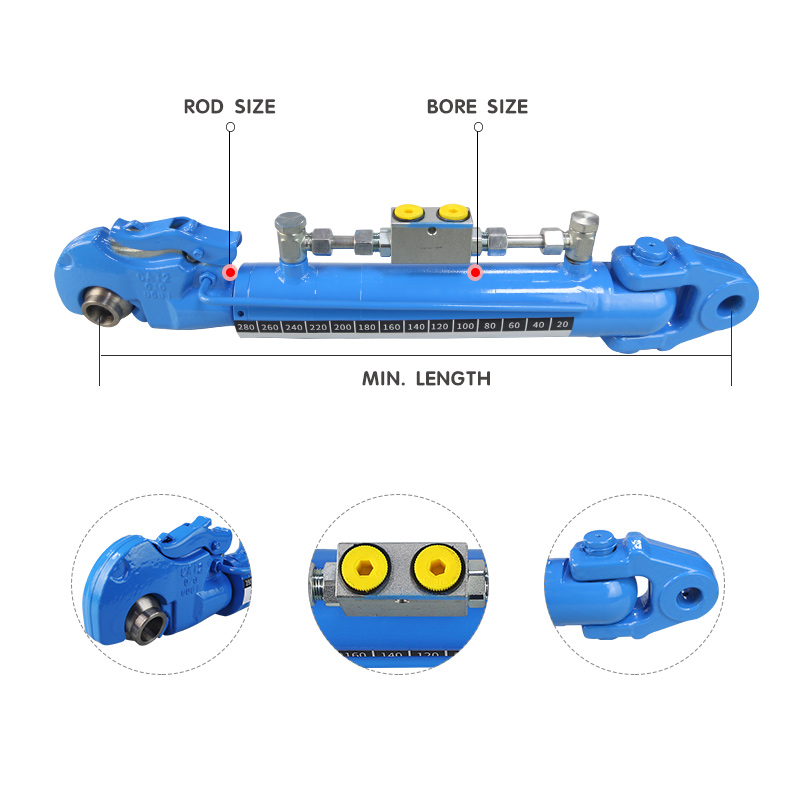

Detailed Drawing

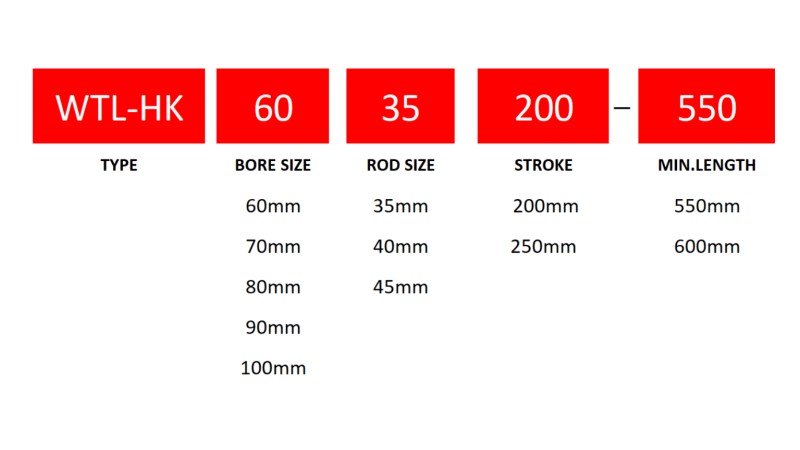

Modle Code System

Hydraulic Top Link Cylinder

The hydraulic top link we provide replaces the tractor's original top link and streamlines your daily tasks. This necessitates the tractor having a double-acting control valve, which, when coupled with the built-in locking block, creates an unbeatable combination.

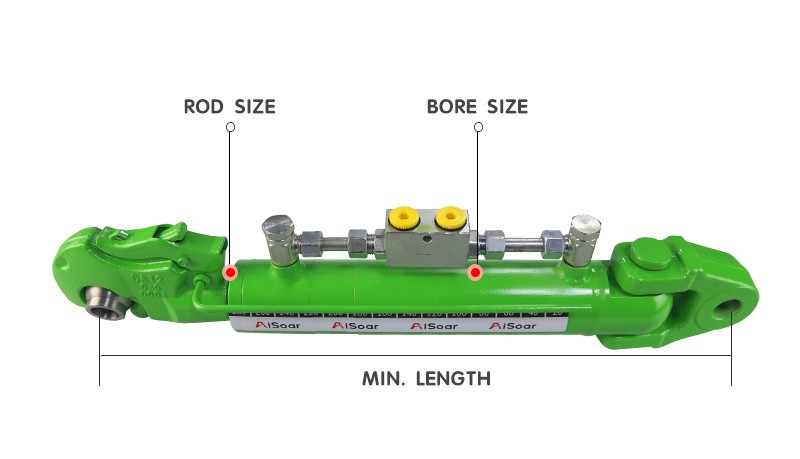

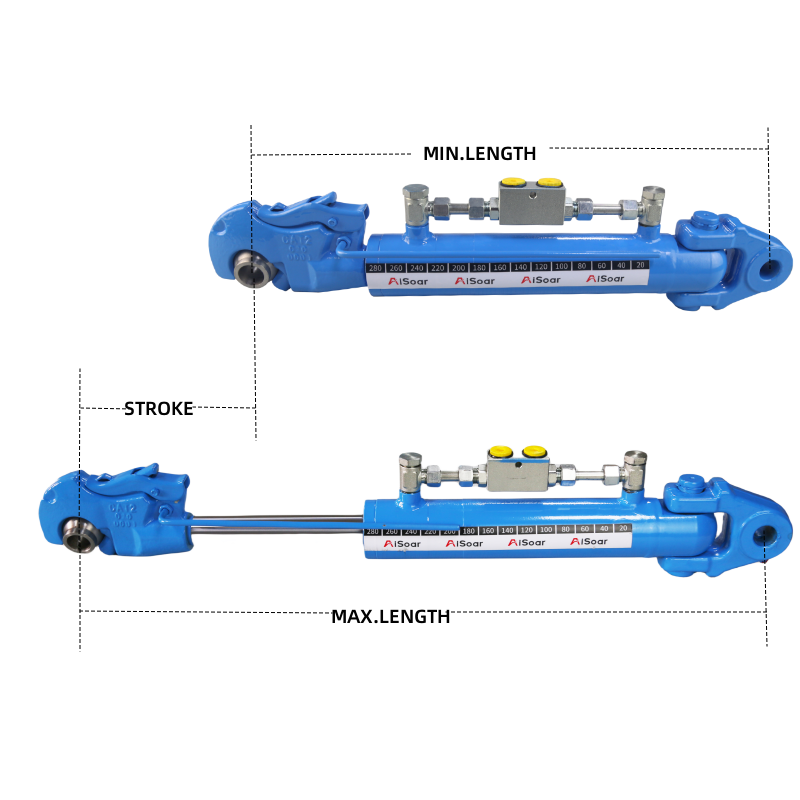

Hydraulic Top Link Cylinder Drawing

We can check the main sizes in below drawing

| ΦA(BORE) | ΦC | E | ΦB | ΦD | F | S | K | T | P |

| 60 | 35 | 350 | 70 | 25.4/29 | 51 | 105 | 51 | 95 | G3/8 |

| 70 | 35 | 350 | 80 | 51 | 105 | 51 | 95 | G3/8 | |

| 80 | 40 | 400 | 95 | 51 | 132 | 51 | 95 | G3/8 | |

| 90 | 40 | 400 | 105 | 51 | 132 | 51 | 95 | G3/8 |

Data Table

Here we can see importants dimensional datas for Top Link cylinders

Order Code ΦA ZStroke E B C S Categorise T Vol(liter) Peso Weight(Kgs.)

| Order Code | ΦA | ΦB | ΦC | Stroke | E+Stroke | F | G | K | S | ΦD | Categorise range | P | T | Thrust t @2600PSI | Lift t @2600PSI | Vol(Liter) | Weight(Kg) |

| WTL-HK60×35×200-595 | 60 | 70 | 35 | 200 | 595 | 51 | 115 | 50 | 124 | 25.4 28.4 | Cat.2 | G3/8" | 117 | 5.1 t | 3.3 t | 0.55 | 12.5 |

| WTL-HK60×35×250-645 | 250 | 645 | 0.7 | 13.5 | |||||||||||||

| WTL-HK70×35×200-595 | 70 | 80 | 200 | 595 | 6.9 t | 5.2 t | 0.95 | 14 | |||||||||

| WTL-HK70×35×250-645 | 250 | 645 | 1.15 | 15.5 | |||||||||||||

| WTL-HK80×40×200-625 | 80 | 95 | 40 | 200 | 625 | 128 | 25.4 | Cat.3 | 9.0 t | 6.8 t | 1.1 | 18 | |||||

| WTL-HK80×40×250-675 | 250 | 675 | 1.35 | 20 | |||||||||||||

| WTL-HK90×40×200-625 | 90 | 105 | 200 | 625 | 11.4 t | 9.2 t | 1.3 | 19.5 | |||||||||

| WTL-HK90×40×250-675 | 250 | 675 | 1.65 | 22 | |||||||||||||

| WTL-HK100×45×200-625 | 100 | 115 | 45 | 200 | 625 | 14.1 t | 11.2 t | 1.55 | 22.5 | ||||||||

| WTL-HK100×45×250-675 | 250 | 675 | 1.9 | 25.5 |

Get Your Top Link HYDRAULIC CYLINDER Today!

Call us or visit our website to get more information about the hydraulic cylinders you need.

Material

We Always Use Good Quality Material For Our Top Link Cylinders

- ROD:C1045 Steel, f7, 25 microns chrome plated.

- TUBE:C1020.

- GLAND:C1045.

- PISTON:C1020.

- PORTS: G3/8.

- Valve: Twin-type non-return valve

- SEALS:Hallite.

- Nut: M18

- Banjo Bolt: G3/8

- Washer: G3/8

- PAINT:Black(STD), color and other custom colors are available.

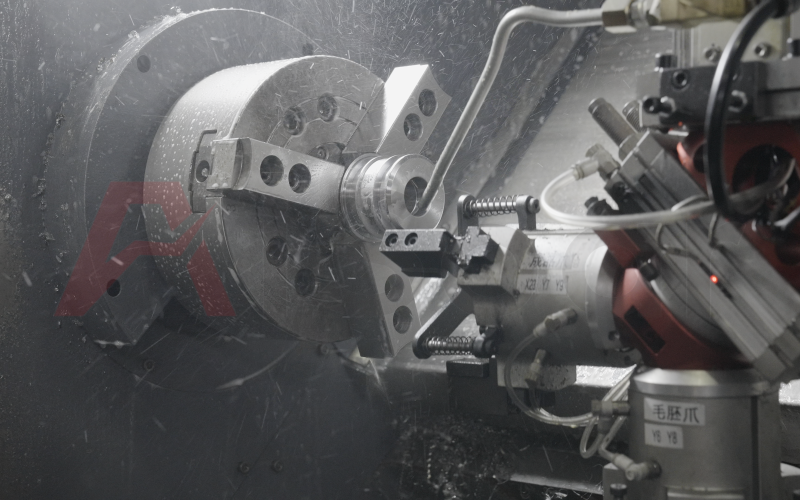

Production Processes

How We Produce Top Link Hydraulic Cylinders

Our Factory

Our Factory

OEM Custom Service is Available

What Kind Of Cylinders Do You Need?

ODM/OEM Order Are Welcome For Us

As a leading manufacturer of tractor cylinders, we are proud to offer ODM and OEM services to meet the diverse needs of our clients. Our extensive experience in the industry ensures that we can deliver high-quality, customized solutions tailored to your specific requirements. Whether you need unique designs or branded equipment, our advanced manufacturing capabilities and rigorous quality control processes guarantee exceptional performance and reliability. Partner with us to benefit from our expertise, innovative technologies, and commitment to excellence. We welcome your ODM/OEM orders and look forward to helping you achieve your goals with our superior tractor cylinders.

Tractor Top Link Hydraulic Cylinder Manufacturer

As a premier manufacturer of tractor top link hydraulic cylinders, we specialize in delivering robust and reliable solutions tailored to enhance the performance and efficiency of your agricultural machinery. Our top link hydraulic cylinders are engineered with precision, using high-quality materials and advanced manufacturing techniques to ensure durability and optimal functionality in demanding environments. We understand the critical role these components play in the stability and versatility of your tractor, and our products are designed to provide seamless adjustment and control. Trust our expertise and commitment to quality to provide you with superior hydraulic cylinders that meet and exceed industry standards, ensuring your equipment operates at its best.

FAQ

Frequently Asked Questions

A:Installation is different; the hydraulic cylinder with a ball joint makes it easier to hang the belongings.

The force is different; the hydraulic cylinder with ball joint maximum cylinder diameter is 80 mm,, the other one is 100 mm.

A: With the locking valve, the adjusted position is maintained even after a long period of time.

The Lock port size is G3/8.

A: Hydraulic cylinder,hose×2, Banjo Bolt×2,Washer×4

Get a Quote Now

ANYTHING YOU COULDN'T FIND?

Talk with one of our sales representatives

Hydraulic Cylinder Manufacturer? Contact Immediately For Consultation.

Send us an email

Contact Us

Have any question about our AiSoar Hydraulic?Please contact us and we will get back to you immediately.

ES

ES RU

RU