Hydraulic Trailer Jack

OEM Custom Hydraulic Trailer Jack

AiSoar hydraulic jack with 12,000 lb capacity offers high-performance and versatility for your lifting needs. Designed for both bolt-on and weld applications, it seamlessly integrates into your existing setup with ease. Its double-acting mechanism ensures efficient operation in both directions, while guide bearings eliminate metal-on-metal friction and galling, ensuring smooth and reliable performance. Compatible with all hydraulic pumps up to 3,000 PSI, it offers maximum flexibility in your hydraulic system. With a painted body for enhanced durability and 26" of power up and power down travel, our hydraulic jack is the ultimate solution for your lifting requirements.

| Environment | High temperature(high temperature resistant seals), cold (cold resistant seals) and other special fluid type. |

| Material | 304, 316 stainless steel, brass and etc. |

| Size | custom bore size/rod size/stroke lengths. |

| Structure | Single Acting Hydraulic Cylinder |

| Application | Trailer |

| Lifting Capicity | 1200 Pounds |

| Valve | Dual Holding Valve |

Atlas hydraulic jack is designed for medium-duty trailers; its swivel foot ensures solid ground contact, and guide bearings eliminate metal-on-metal friction and galling for most major hydraulic pump manufacturers. It is designed to tie into existing truck or trailer hydraulics.The hydraulic jack is intended for use on goose-neck, dump, tilt, and utility trailer lift and stabilizing applications.

Hydraulic Trailer Jack

OEM Cylinder Types

Hydraulic Trailer Jack

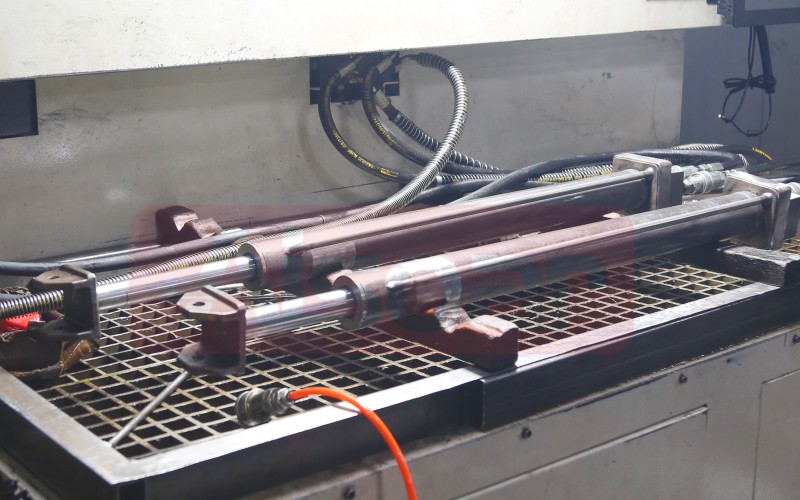

Production Process

OEM Custom Welded Hydraulic Cylinders

Call us or visit our website to get more information about the hydraulic cylinders you need.

Manufacturing

AiSoar Custom Hydraulic Jack is Your Best Choice

1. We are a family owned company with a full staff of engineering, production, quality control, sales and customer service departments. Our factory covers an area of 13,000 square meters with modern standard workshops and more than 200 sets of cutting edge equipment.

2.We have more than 20 years' experience designing and manufacturing custom hydraulic cylinders. Our development has put a lot of time and effort into organizing standardized modules and standardizing process flow. Now that we have modular standard elements, we use a PLM system to manage the drawings, and we use a MES system for documentation, traceability, and data transparency. But also, AiSoar custon product according to your application.

3. Short-run production for custom cylinders, even just 1 pc, is supported. For customized hydraulic cylinders, huge-size orders are preferred, mid-size batch orders are fully supported, and small orders are acceptable for long-term customers. By standardizing and optimizing components' specifications, we can integrate resources and apply them to different customers' orders. By doing this, even when an individual purchase order is not on a large scale, components' costs can still be much lower.

4. We take care of our cylinders like our children. We manufacture all our parts in-house, so the quality of our hydraulic cylinders is super good. Before assembly, we clean all the parts with a high-pressure cleaning machine, and we flush before testing. Each cylinder would go through the testing procedure before packaging to make sure there was no internal or external seal leakage. Paint with primer first before the main paint to make sure the cylinders look perfect.

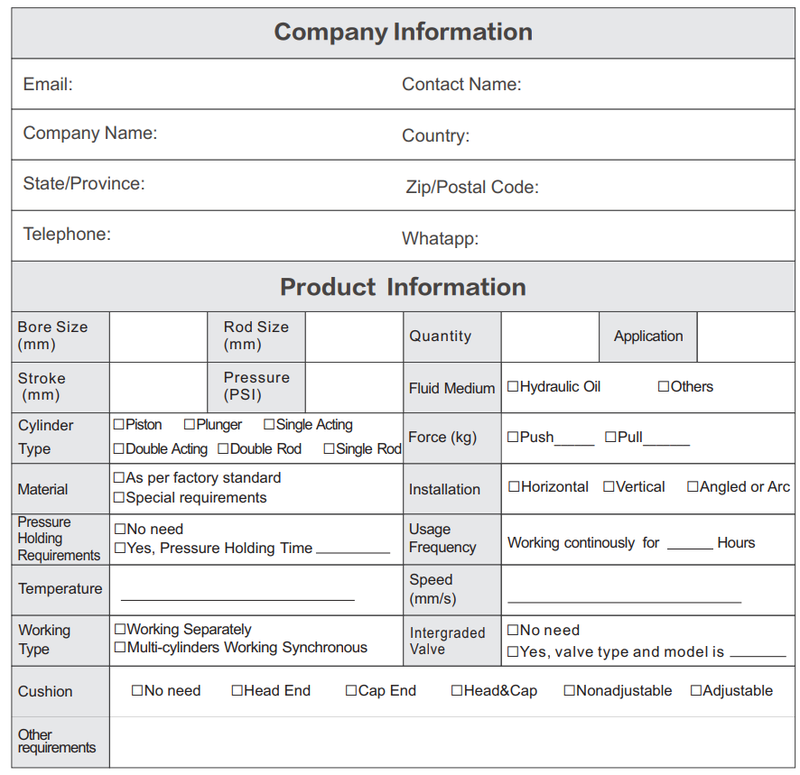

Custom Guide

Custom Welded Hydraulic Cylinders Guide

Firstly, you should determine the technical parameters: bore size, rod size, stroke, working pressure, and required force (column load).

It is greatly useful if you can tell us the application of cylinders, complete this form, and return it by email to oversea@ai-soar.com. If you prefer, provide contact information on this page and follow up with your cylinder print.

Secondly, you should select the proper mounting types for rod ends or body that can meet your application's demands. Consider the space requirements and how the load functions.

Other information :Application, Single- or double-acting type, Retract or closed length,Stroke length,Outside diameter of the largest,Mount type,Mounting sizes,Number of moving stages

If you provide as mentioned above information, AiSoar can recomend hydraulic cylinder for you

Contact UsGet a Quote Now

ANYTHING YOU COULDN'T FIND?

Talk with one of our sales representatives

Hydraulic Cylinder Manufacturer? Contact Immediately For Consultation.

Send us an email

Contact Us

Have any question about our AiSoar Hydraulic?Please contact us and we will get back to you immediately.

ES

ES RU

RU