How Does a Hydraulic Cylinder Work?

As we all know that a hydraulic cylinder is one of the main components of a hydraulic system. It is a mechanical actuator that produces linear motion and acts as a muscle for the machine. Hydraulic cylinder structure is simple and reliable. In the realization of reciprocating movement, it can be removed from the deceleration device without transmission gap. It is widely used in a variety of mechanical hydraulic system. A hydraulic cylinder generates power by exerting force to liquid through the linear motion of the piston. These cylinders are connected to each other, filled with hydraulic oil, and equipped with appropriate pistons on each side. When pressure is exerted onto the piston, pressure is transmitted through the fluid.

Above is the general working principle of the hydraulic cylinder. As we have written in our previous blogs, hydraulic cylinders can be divided into double acting cylinders and single acting cylinders according to the acting type. What I’m telling is the working principle of single acting and double acting hydraulic cylinders is different. You could find their difference structure from pictures below.

How Do Single Acting Hydraulic Cylinders Work?

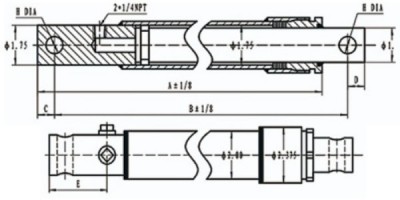

In this type, hydraulic cylinders usually include just one port where the hydraulic oil enters and forces the piston out in a singular direction. The piston rod in the cylinder barrel can push outwards but cannot pull back. Thus, it is required an extra pressure in the opposite direction to make the rod back.

Single acting hydraulic cylinder

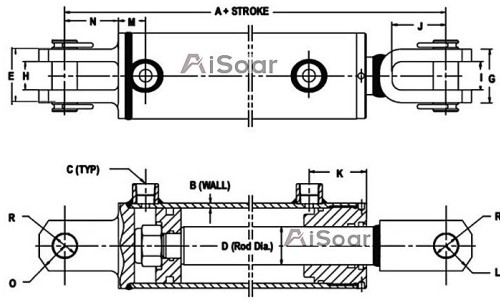

Double acting hydraulic cylinder

How Do Double Acting Hydraulic Cylinders Work?

Double acting hydraulic cylinders are equipped with two ports, respectively on the rod ends and base ends. The function of these two ports is to control the flow and movement of fluid back and forth. The piston retracts when hydraulic oil is pumped into the top port, then the piston will be forced into its original position. On the other hand, the piston extends when pumping fluid to the head end. For projects requiring repetitive accuracy, double-acting cylinder is a better choice because of its faster and predictable shrinkage.

How Do Double Acting Hydraulic Cylinders Work?

Double acting hydraulic cylinders are equipped with two ports, respectively on the rod ends and base ends. The function of these two ports is to control the flow and movement of fluid back and forth. The piston retracts when hydraulic oil is pumped into the top port, then the piston will be forced into its original position. On the other hand, the piston extends when pumping fluid to the head end. For projects requiring repetitive accuracy, double-acting cylinder is a better choice because of its faster and predictable shrinkage.

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Mobilephone: +8618258822266

EMAIL: sales@ai-soar.com

ES

ES RU

RU