Hydraulic Pumps

Detailed Drawing

Supply Range

Honed Hydraulic Pumps

We produce the hydrualic cylinders, power units, hydrualic parts and related accessories, such as head, cap, piston rod, rod ends, tube, seal kits, and etc.

| ITEM | Description | |||||||||

| The parts of hydrualic cylinder | Head, Cap, Piston, Gland, mounting parts. | |||||||||

| Steel Tube/ Barrel | Steel grade E355 / St52 / Fe510 / 1524 / 1024,steeless, chrome plated is available | |||||||||

| Piston rod/ Chrome plated steel bar | Steel grade C45E / Ck45 / C45 / 1045, steeless, NiCr or induction hardened is available | |||||||||

| Rod ends | Spherical Rod Eye, Spherical Plain Bearing, I connecting, T connecting, Clevis are fully supported. | |||||||||

| Seal kits | Domestic brand in China, or international brand are optional. | |||||||||

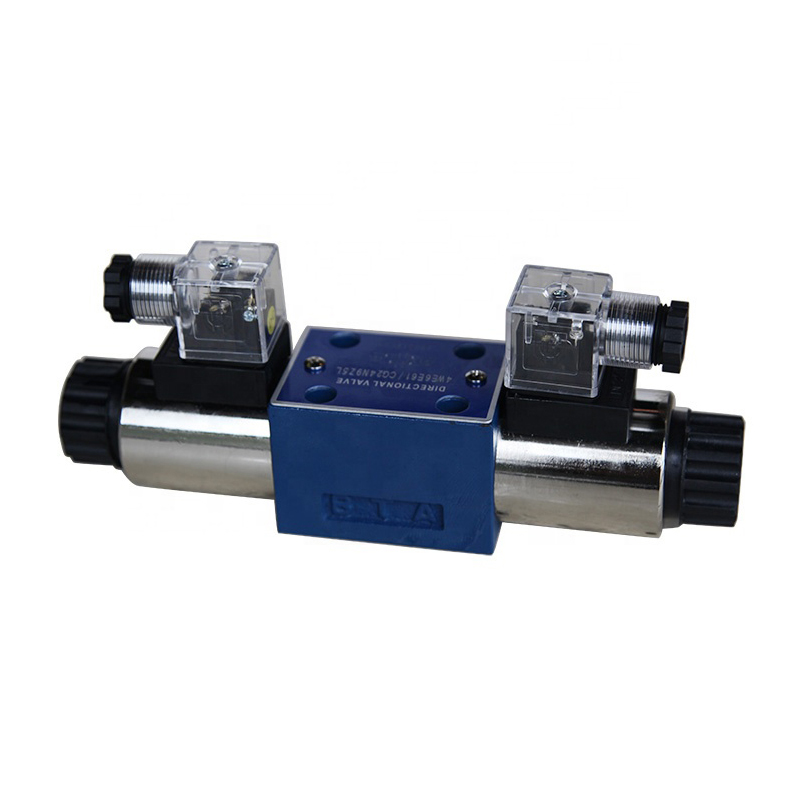

| Hydraulic valve group | Including the manifold, hydraulic valves made in China or international brand. | |||||||||

| The related accessories of power system | Hydraulic pump, motor, pipe, connector and etc. | |||||||||

Hydraulic pumps are used in hydraulic drive systems and can be hydrostatic or hydrodynamic. A hydraulic pump is a mechanical source of power that converts mechanical power into hydraulic energy (hydrostatic energy i.e. flow, pressure). Hydrodynamic pumps are more frequent in day-to-day life. Hydrostatic pumps of various types all work on the principle of Pascal's law.

Get Your Honed Hydraulic Pumps Today!

Call us or visit our website to get more information about the hydraulic cylinders you need.

Types

Different types of pump for your choice

Gear pumps (with external teeth) (fixed displacement) are simple and economical pumps.

Production Processes

How We Produce Honed Hydraulic Pumps

Our Factory

Our Factory

FAQ

Frequently Asked Questions

We'll try to answer some of your questions

A: Sure, we have the ability to supply customiezed service. TR series tie rod cylinder is the standard type, but customized stroke, intergraded valve and special tube/rod material is available.

A: Definitely yes, we have our own factory. We would like to show you videos via WhatsApp or Wechat.

A: 1" pin hole for bore size 1"~4", and 1.25" pin hole for bore size 5".

A: Yes, it's a rebuild-able cylinder and we do offer repair kits. Tie rod type is easy to repair.

A: Retracted length from center pin to center pin, we also call out min. length or closed length. Extended length is the retracted on centers plus the stroke, we also call out max. length or open length.

Aisoar Hydraulic Cylinders Catalogue

Hydraulic pumps are used in hydraulic drive systems and can be hydrostatic or hydrodynamic. A hydraulic pump is a mechanical source of power that converts mechanical power into hydraulic energy (hydrostatic energy i.e. flow, pressure). It generates flow with enough power to overcome pressure induced by the load at the pump outlet. Hydraulic pumps are more frequent in day-to-day life.

DownloadGet a Quote Now

ANYTHING YOU COULDN'T FIND?

Talk with one of our sales representatives

Hydraulic Cylinder Manufacturer? Contact Immediately For Consultation.

Send us an email

Contact Us

Have any question about our AiSoar Hydraulic?Please contact us and we will get back to you immediately.

ES

ES RU

RU