Tie Rod Vs Welded Hydraulic Cylinders

Hydraulic cylinders are the most practical and useful of fluid power components, and for this reason, they have inevitably evolved into an almost endless array of configurations, designs and sizes.

Here are two popular classes of hydraulic cylinder: tie-rod cylinders and welded cylinders. We will guide you in choosing the best cylinder type to suit your needs.

Before you can decide on which type of cylinder to purchase there are a few factors you need to consider. These are bore size, rod size and stroke length.

Bore size – This is the inside diameter of the cylinder.

Rod size – This is the diameter of the piston rod.

Stroke – This is the distance that the piston travels between the fully extended and fully retracted positions.

The bore, rod and stroke measurements are related to the mass of the load to be moved and the available system pressure.

TIE-ROD

Tie-rod cylinders are most often used in industrial factory applications. They use high strength, threaded steel rods and nuts to hold square or rectangular end caps to each end of the cylinder barrel. Seals are placed between the barrel and end cap to prevent leakage.

Smaller cylinders usually use 4 tie-rods, but larger bore cylinders can use up to 20.

Tie-rod cylinders are useful because they are not as complex in design as welded-body cylinders and can be completely disassembled for service and repair.

WELDED BODY

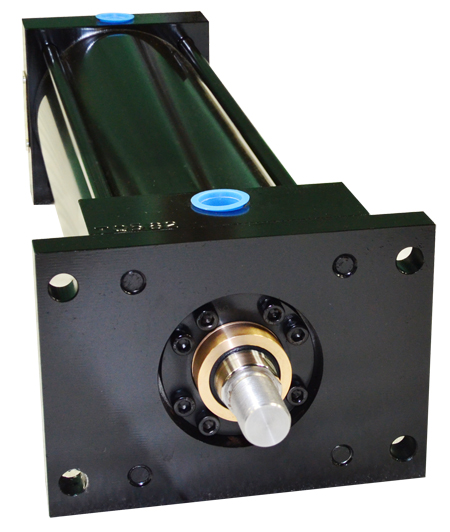

The main feature of the welded body cylinder is that the end caps are welded directly onto the barrel. Welded cylinders have a narrower body and usually a shorter overall length than the tie-rod type, which enables a tighter fit into the confines of machinery design.

The absence of tie-rods means that the welded cylinder is not prone to tie-rod related failure such as stretching, and the design allows for easier customization of the cylinder body if this is a requirement. The welded cylinder design is lighter and more compact, and is therefore highly utilized in mobile equipment for construction and other rugged applications.

SUMMARY

Welded cylinder types are good for high volume production and tie-rod cylinder types offer great flexibility of design with large families of compatible parts.

Here are a few considerations when weighing up which cylinder type is best for your application.

SELECT THE TIE-ROD CYLINDER IF:

- There is sufficient space for the installation

- The operating conditions cause a need for efficient maintenance, repair and assembly

- You are running a lower pressure application

- You face budget constraints and require a lower-priced product

SELECT THE WELDED BODY CYLINDER IF:

- Installation space is limited and/or mobility is an important factor

- You are running a higher pressure application

- You are interested in superior seal packages

- Appearance is a selection factor, you require a lower profile unit

- You require greater durability, pressure and loading capabilities

- You have special customization requirements for the oil port, lock valves or balancing valves

At Aisoar we specialize in hydraulic cylinders. Now that you know whether to choose a tie-rod or welded cylinder for your application, request a quote online.

Hangzhou Aisoar hydraulic technology Co.,Ltd

Tel: 86-571-87920309

Fax: 86-571-87926329

Mob&Wechat&Whatsapp: +86 13588456446

Email:Jack@ai-soar.com

ES

ES RU

RU