What are Mounting Type of Hydraulic Cylinders?

Choosing the right hydraulic cylinder for your application needs remains a key point for hydraulic cylinder design and manufacturing. Selecting the propery hydraulic cylinder mounting types can minimize accelerated wear and tear in addition to keeping your cylinder running at optimal performance levels. Stability and strength provided by hydraulic cylinder mounts can also may be beneficial to prevent misalignment issues that can cause hydraulic cylinder failure.

Hydraulic cylinder mounting type means how to install the hydraulic cylinder on your equipment. A basic hydraulic cylinder without rod end connections or base ends, just with drilled holes or thread, can be installed on the machine.

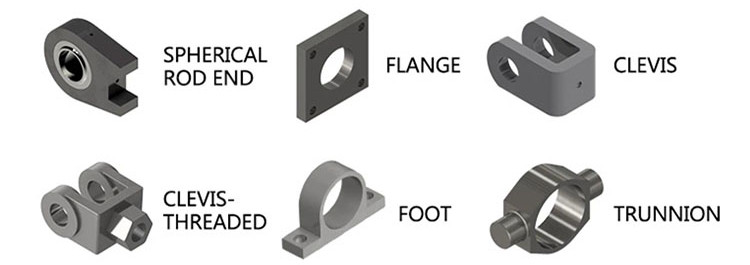

We can discuss the mounting type on three components of the hydraulic cylinder: rod ends, base ends, and body

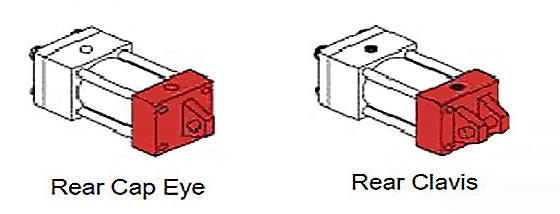

Rod ends type means the end type of rod or the attachment of rod, which includes drilled hole, threaded, fixed eye, cross-tube, clevis, flange, spherical plain bearings, ball head, etc. Base ends type means the end type of base or cap, which includes drilled hole, fixed eye, cross-tube, clevis, flange, spherical plain bearings, trunnion, etc.

Body type refers to the shape of the body, whether it is bare barrel, weld-on flange, food, trunnion, or something else. For the welded hydraulic cylinder, the rod ends and base ends are welded on the body mostly, but for the tie rod type, the base ends are tightened by tie rods, and the attachment is mostly threaded on the rod ends.

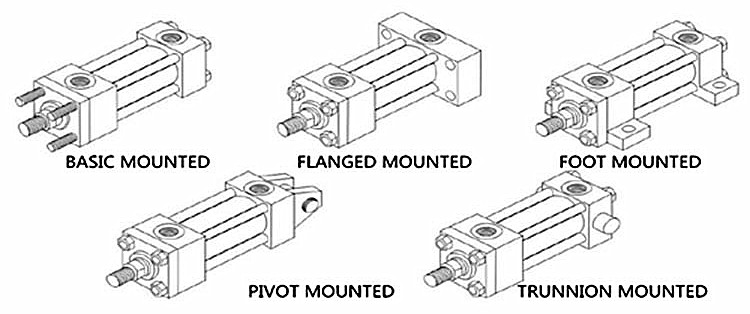

Common mount types including:

Flange mounting / Clevis mounting / Trunnion mounting /Centerling mounting/Foot mounting

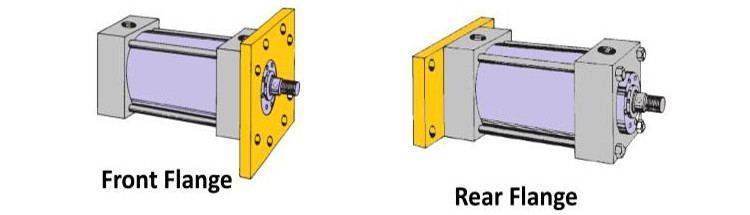

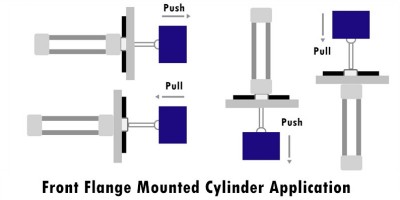

Flange mounting—Flanges are the parts that connect pipes together. Bolts can pass through the holes in the flange. There are various types of flanges, including rectangular flanges, square flanges, round flanges, and others. Flange mounting is suitable for transmitting linear force and has the advantage of being very strong.

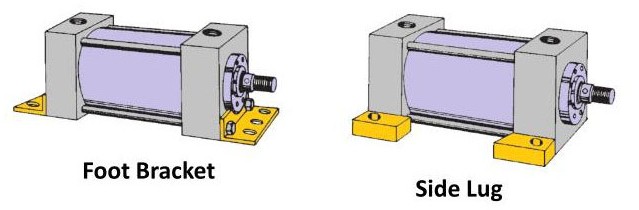

Foot mounting—It is applicable to the fixed installation of the hydraulic cylinder during the working process, and its installation plane is not in the same plane as the cylinder central axis . When selecting this kind of installation, the installed structure must be well positioned and fastened. The installation methods include end and side lug installation.

Earring Mounted and Clevis mounting—It is applicable to the working condition that the force of the hydraulic cylinder causes the moving machine components in it to generate a curved motion path along the same motion plane. When driving the machine components for angular operation, the force of the rotating torque is proportional to the angle of the force generated by the lever arm of the machine connecting rod mechanism and the hinged installation.

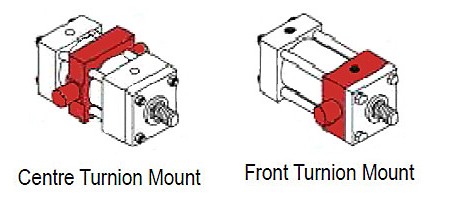

Trunnion mounting —Absorb force on the cylinder centerline and make the cylinder change alignment in one plane. Common types include clevises, trunnion mounts and spherical bearings. Because these mounts allow a cylinder to pivot, they should be used with pivoting rod-end attachments that also pivot. Clevis mounts can be used in any orientation and are generally recommended for short strokes and small- to medium-bore cylinders.There are three installation positions: front , middle and rear.

Swivel Ball End Mounted Hydraulic Cylinders—Connect the swivel ball end of the hydraulic cylinder with the ball seat on the machine so that the hydraulic cylinder can swing freely within a certain space.

The ball end mounted hydraulic cylinder has a large degree of freedom, but its stability is not quite good.

Centerline mounting----It is the best method of mounting the cylinder. In this method, cylinder is mounted along with its centerline. In this mounting a specail flange bolted at center is usd to mount the cylinder.

Pivot Mounting---A cylinder may have Rotational feedom while it is reciprocating. There is three types of pivot mountings, Clevis mounting, Trunion mounting, Tang mounting. Pivot mounting can be self-changing the centerline of cylinder to meet the varied loading direction, is ideal mounting type for side loading which is unequal pressure that is not centered on the cylinder rod. This off-center strain can lead to bending of the rod in extreme cases, but more commonly causes leaking due to warping the circular seals into an oval shape.

Special Mounting

Focused on hydraulic cylinders for more than 20 years, we are quite capable of designing and making customized hydraulic cylinders, including the special mounting.

How to design the best mounting type of hydrualic cylinder?

It depends on the application of the hydraulic cylinder. It should be considered the installation space and the min. and max. mounting sizes of hydraulic cylinders, and in the meantime, we have to consider the requirements of force, pull type, or push type. The forces on the piston face and the piston head retainer vary depending on which piston head retention system is used. We can see some typical mounted applications as below, the ideal applications for pull and push types.

As a Quality Hydraulic Cylinder Manufacturer and Supplier in China, Aisoar Hydraulics is willing to grow with all partners and to support them in every possible way.

Have any questions ,please contact us!

Hangzhou Aisoar hydraulic technology Co.,Ltd

Tel: 86-571-87920309

Fax: 86-571-87926329

Mob&Wechat&Whatsapp: +86 13588456446

Email:Jack@ai-soar.com

www.aisoarhydraulics.com

ES

ES RU

RU