How to Design A Hydraulic Cylinder?

How to Design A Hydraulic Cylinder?

Hydraulic Cylinder Design Standards

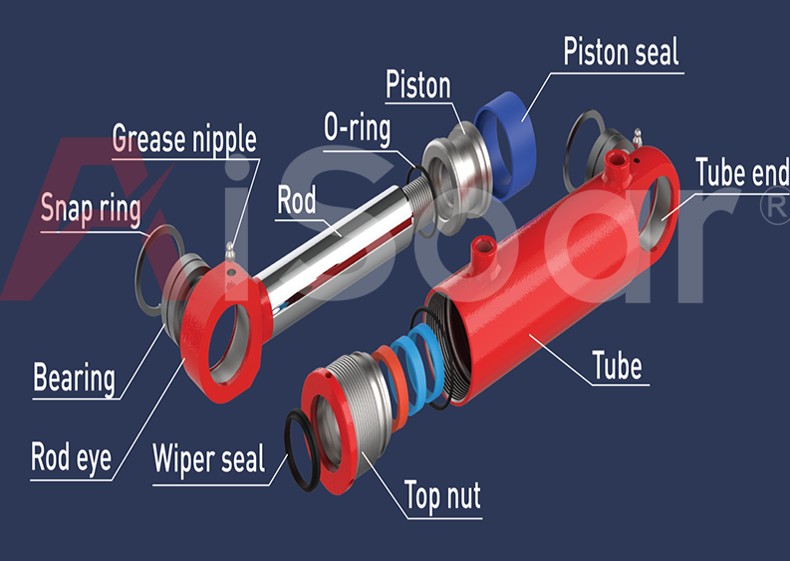

Hydraulic cylinder is a kind of complicated device containing a great deal of components in the environment of industrial manufacturing. Many factors are to be considered in the process of designing a hydraulic cylinder. None of these factors should be ignored because it will cause the design mistakes. Different working conditions of hydraulic cylinders affects the design standards. For instance, hydraulic cylinders used in construction industry versus agricultural industry require other design material. The following are some factors that should be considered in the process of designing a hydraulic cylinder.

Working Conditions

Working conditions are the important factors: where the hydraulic cylinder is designed to do and what kind of working capacity it needs to bear. If the hydraulic cylinder is used in underwater conditions, technicians should consider how to prevent the water from flowing into hydraulic oil. The marine environment requires hydraulic cylinder with high corrosion resistance. Similarly, if the hydraulic cylinder is working in the construction equipment, it should withstand extreme load and temperatures.

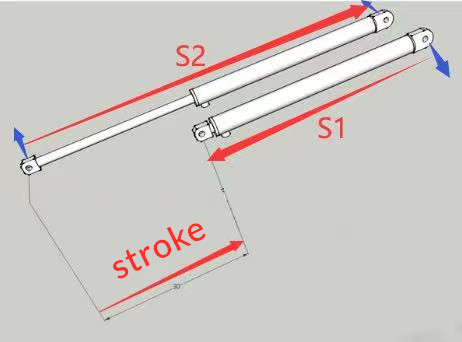

Stroke Length

It is essential to thinking about the stroke length which is affecting the proper rod size for you to custom hydraulic cylinder. The increasement of rod size and stroke length of a hydraulic cylinder may cause the changing of the loads. A large cylinder should be designed with long stroke length so that it does not buckle.

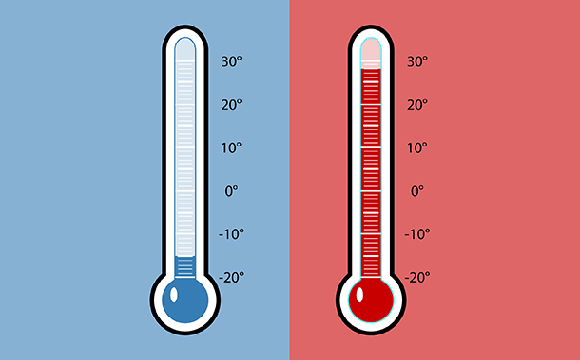

Temperature

High temperature or low temperature conditions affects the choosing of hydraulic fluid. For example, water-based fluid or synthetic fluid with thermal stability are selected for applications of higher fire resistance requirements because high temperature will evaporate the water in the oil.

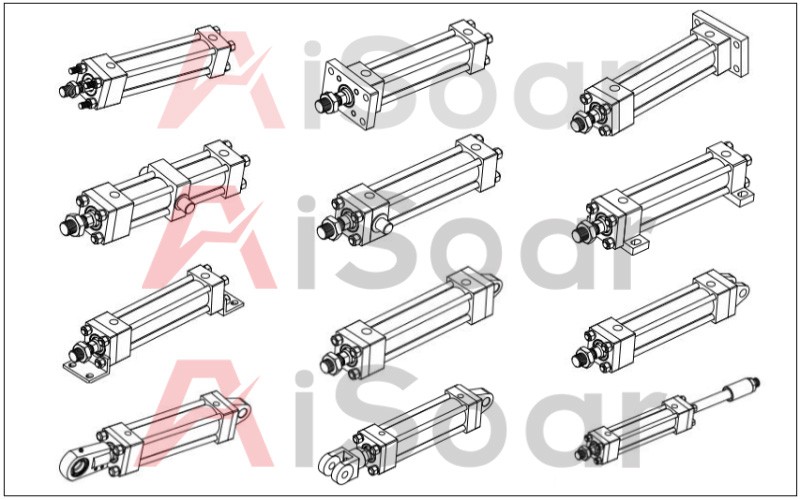

Mounting Styles

There are several advantages and limitations of each mounting style. When customizing a hydraulic cylinder, you need to choose an appropriate mounting style according to your application. In Aisoar Hydraulics, there are seven mounting options of customized welded hydraulic cylinders: clevis, cross-tube, flange, tang, trunnion, spherical bushings and foot mount. As for customized tie rod hydraulic cylinders, mounting options are tie-rod extended, flange, trunnion, fixed eye clevis and foot mount.

Welded hydraulic cylinder

Tie-rod hydraulic cylinder

However, designing and customizing a hydraulic cylinder should not only consider the factors mentioned above, there are many other factors such as working pressure, duty cycle, bore size and so on. If you want to know more steps of designing and customizing a hydraulic cylinder, welcome to consult us.

AISOAR HYDRAULIC CYLINDERS

Hengxin Mansion, No. 588, Jiangnan Main Road, Changhe Street, Binjiang District, Hangzhou City, Zhejiang Province, China

TEL: +86-571-87920309

Contact name: Tracy

Mobilephone: +8618248492500

Wechat: aisoar03

EMAIL: tracy@ai-soar.com

ES

ES RU

RU