How much do you know about telescopic hydraulic cylinder?

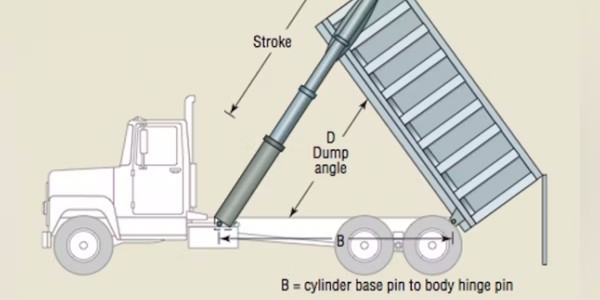

Telescopic hydraulic cylinders are widely used in various fields, particularly in mobile applications. The ability of this cylinder design to give an unusually long stroke while preserving a relatively modest retracted length is its greatest advantage. When mounting space is limited and a long stroke is required, a telescopic cylinder is the solution.

Depending on the number of stages, a telescopic cylinder, also known as a multi-stage cylinder, can have a collapsed length as short as 20% of the fully extended cylinder length.

Telescopic Hydraulic Cylinder Design

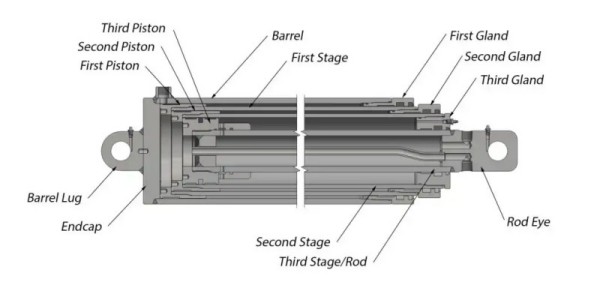

The smallest part is referred to as the rod or plunger, while the greatest diameter tube is termed the barrel, just like in a traditional single rod cylinder. A telescopic cylinder has one or more stages, which are nested tubes with a decreasing diameter from the outer barrel. It appears that six steps is the maximum number. It is theoretically possible to create a cylinder with more phases, but stability becomes a problem. The cylinders with three or four stages are rather common.

A telescoping cylinder's stages usually go from largest to smallest. Before the following stage moves, the largest stage will finish its stroke. This keeps going until the cylinder reaches its total extended length and all stages are fully stretched.

Types of Telescopic Cylinders

Types of Telescopic Cylinders

Single Acting Telescopic Cylinders

The most basic and widely used design is the single acting telescopic cylinder. It is extended by hydraulic pressure, just like a single rod cylinder, and it retracts with the help of an outside force, such gravity. Retraction of the cylinder occurs when fluid pressure is released into the reservoir, allowing the weight of the load to overcome mechanical losses and friction. Single acting cylinders are used when some form of load is always present such as a dump body on a dump truck.

Double Acting Telescopic Cylinders

Hydraulic pressure is used by a double action telescopic cylinder to expand and retract. Although the design is more complicated than its single acting equivalent, it is the sole choice in situations when control over the retract cycle is needed or when there is no external retract force. Garbage compactors, roll-on/roll-off trucks, and excavator shovels are examples of classic applications.

The advantages of telescopic hydraulic cylinder

The main advantage of using a telescopic hydraulic cylinder, is that they can be made as single acting, double acting, or a single / double acting combination. By selecting a combination single acting / double acting telescopic cylinder, you get the added benefits and functionality of a double acting hydraulic cylinder with the ease of operation and cost-effectiveness of a single acting hydraulic cylinder. Telescopic hydraulic cylinders are also space-saving and may suit precise angle needs.

At AiSoar, we have more than 20 years of experience manufacturing hydraulic cylinder ,hydraulic system and hydraulic testing machine. We are an experienced and trusted company with a book of loyal customers. If you are interested in working with us, or have any questions about our hydraulic cylinders, please do not hesitate to contact us today!

ES

ES RU

RU