Do you know the function of hydraulic cylinder various seals and rings?

Hydraulic seals are molded according to working temperature, cylinder speed, cylinder operating pressure, working application, and medium.They are usually non-metallic, quite soft rings placed in a housing, or arranged in a mixture of rings creating a sealing unit. This is to separate or block liquid in applications that involve reciprocating motion. Hydraulic seals are crucial in machinery equipment. Their use is vital when it comes to enabling the transformation of liquid into linear motion.

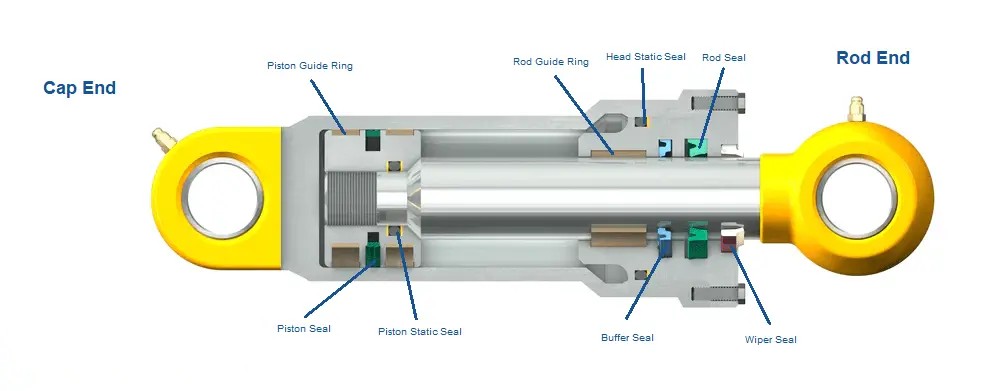

Piston Seals

Piston Seals guarantee liquid or other media do not pass round the piston due to the system pressure pushing the piston down the cylinder amid a stress course. They are generally single-acting seals, which means the stress acts only on one side; and double-acting seals, which means the stress acts on both sides.

Static Seals

Hydraulic static seals prevent fluid leakage in stationary parts of hydraulic system. They create a tight barrier at non-moving junctions, like between a cylinder head and bore, maintaining system pressure and preventing external contamination. Essential for the reliability and efficiency of hydraulic components like valves, pumps, and cylinders, these seals are crucial for system integrity.

Piston Guide Ring

Hydraulic piston guide rings, also known as bearing rings, are used to guide the piston and piston rod within a hydraulic cylinder, ensuring precise linear movement.

They help in absorbing transverse forces that occur during the operation of the cylinder.

Rod Seals

Rod Seals are considered the critical element of a cylinder's sealing system. As the rod moves in and out, these seals prevent hydraulic fluid from escaping the cylinder (dynamic stress sealing). Additionally, Rod Seals work alongside Wiper Seals to protect the hydraulic system from external contaminants such as dust, dirt, and varying external environmental conditions.

Wiper Seals

Wiper seals, commonly known as scraper seals, are integral parts of a sealing configuration, often used with other types of seals. They maintain a snug fit while permitting the smooth passage of a reciprocating rod through their inner bore

Wear rings

Wear rings, they play a crucial role in maintaining the piston's alignment. This positioning ensures uniform wear and stress distribution across the seals, making them essential in both rod and piston assemblies.

Buffer rings

Buffer rings, their primary role in hydraulic cylinders is to shield the rod from pressure fluctuations and shock impacts. Absence of these seals can considerably diminish the operational lifespan of the cylinder.

AiSoar hydraulic cylinders use top quality seals to ensure long cylinder life and high performance. If you have any question about hydraulic cylinder or hydraulic cylinder seals or ring, please let us know ,AiSoar will try best to have a favor for you.

ES

ES RU

RU