Aisoar Hydraulic System

Hydraulic systems are all around us on a daily basis. They're used in vehicles, construction equipment, buildings, and manufacturing facilities. Hydraulics are one of the most efficient ways to create movement when heavy loads are involved or a repetitive motion is needed.

Hydraulic systems in their simplest form are simply a system that uses pressurized fluid to accomplish a task. Simple hydraulic systems have been used even in ancient times but were limited to open systems using gravity to create pressure. Hydraulic systems were revolutionized by the introduction of the pump with which high pressures could be created quickly and easily.

Hydraulic System Components

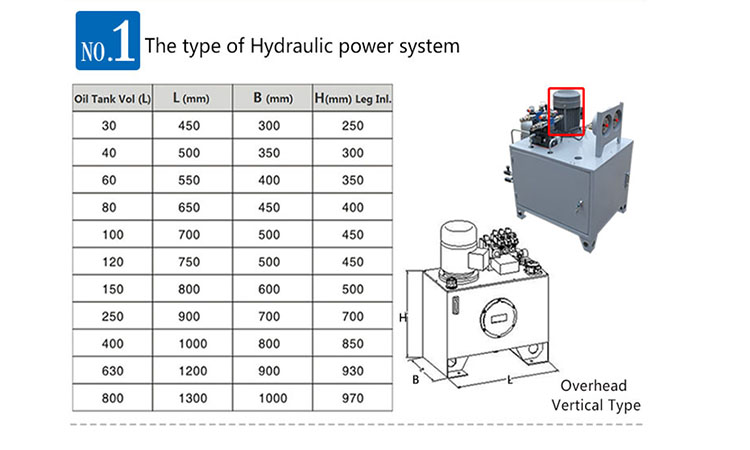

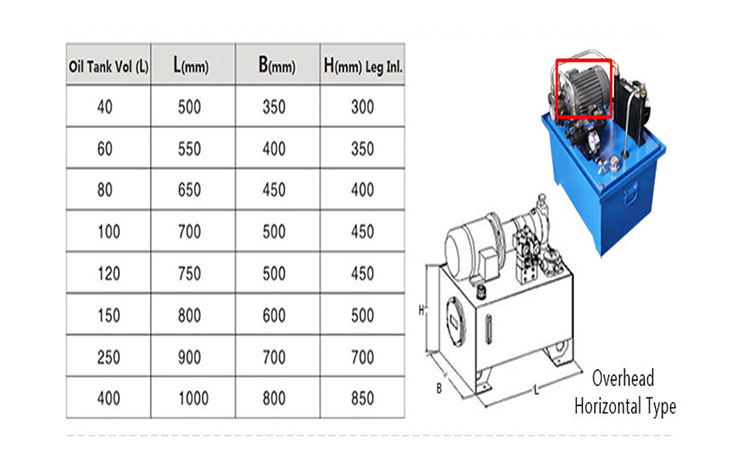

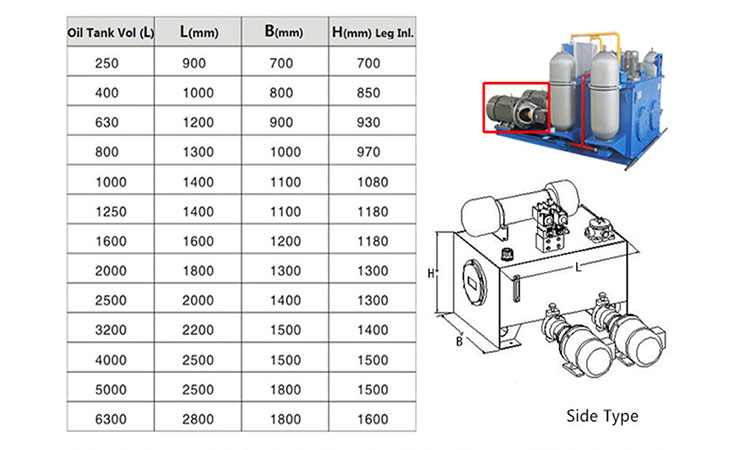

The hydraulic system is divided into vertical, horizontal and side mounted hydraulic systems according to the motor installation mode

Hydraulic components are the basic components of hydraulic system equipment, divided into four categories: hydraulic pumps, control valves, actuators and hydraulic accessories.

(1) HYDRAULIC PUMP

The hydraulic pump is a mechanical energy-hydraulic energy conversion element. It is responsible for providing a hydraulic oil source that meets the requirements for the hydraulic system and is the power element of the hydraulic system. The characteristics of hydraulic pumps are:

(2) CONTROL VALVE

Control valves mainly include pressure valves, directional valves and flow valves.

1. Pressure Valve

It is the pressure regulating and limiting component of the hydraulic system, mainly including various overflow valves, pressure reducing valves and sequence valves. Currently, most pressure valves are secondary valves. Once the pressure valve fails, it will cause pressure imbalance, such as pressure drop, no pressure, pressure fluctuation and non-adjustment, pressure valve core stuck and spring broken, etc. Pressure valve is also the key object of diagnosis and monitoring.

2. Directional Valve

It mainly includes various reversing valves and one-way valves to control the positive and negative flow directions of the on-off of the hydraulic circuit. The reversing valve works intermittently, and its life is calculated by the number of reversal. The damage of the reversing valve is mainly the wear of the valve core mating surface, the valve core stuck, the spring is broken or weak, and the electromagnet is damaged. The reversing valve is easy to install upside down in use, and the spool of the directional valve is also easy to install upside down. After the reversing valve is damaged, the sequence of actions of the hydraulic system will be disordered. The damage of the one-way valve mainly occurs on the sealing surface.

3. Flow Valve

Used to control the flow through the oil circuit to control the movement speed of the actuator, mainly including various speed control valves and throttle valves. The failure of the flow valve mainly lies in the blockage of the orifice and the stuck valve core. After the flow valve fails, the hydraulic system will run out of control.

(3) ACTUATOR

The actuator mainly includes hydraulic cylinders and hydraulic motors.

1. Hydraulic Cylinder

Under the action of hydraulic oil, the load is pushed to move linearly. The damage of the hydraulic cylinder mainly occurs in the seal. The damage of the seal causes the hydraulic cylinder to slow down and crawl, and cause external leakage.

2. Hydraulic Motor

Propelled by hydraulic oil, it produces rotational movement and outputs speed and torque to the load. Hydraulic motors mainly include gear motors, vane motors, axial or radial plunger hydraulic motors. The main damage of the hydraulic motor is the wear of the working parts and moving parts, which increases the gap, which in turn causes the output torque and speed to decrease, the leakage and the vibration increase. In a working cycle, the hydraulic motor works part of the time, and the other part of the time is in a stopped state, and its movement speed is relatively slow. Compared with the hydraulic pump, the wear speed is slow.

(4) HYDRAULIC ACCESSORIES

Hydraulic accessories include seals, filters, accumulators, coolers, etc.

1. Accumulator

Mainly used for absorbing pressure and flow pulsation, as auxiliary energy and system pressure maintaining.

2. Filter

It is used to filter various pollutants in the oil and protect the hydraulic system. It is an important hydraulic component.

3. Oil Cooler / Heat Exchanger

It is used to cool the heat generated during the operation of the system and maintain the temperature balance.

4. Seals

It is a guarantee factor for the hydraulic system to maintain normal pressure. The energy flow of the hydraulic device is consistent with the material flow, and they are communicated back and forth. Therefore, any sealing problem in the hydraulic circuit will cause the deviation of the system energy transmission.

5. Others

Mainly pipe fittings, pipe clamps, joints, instruments, etc.

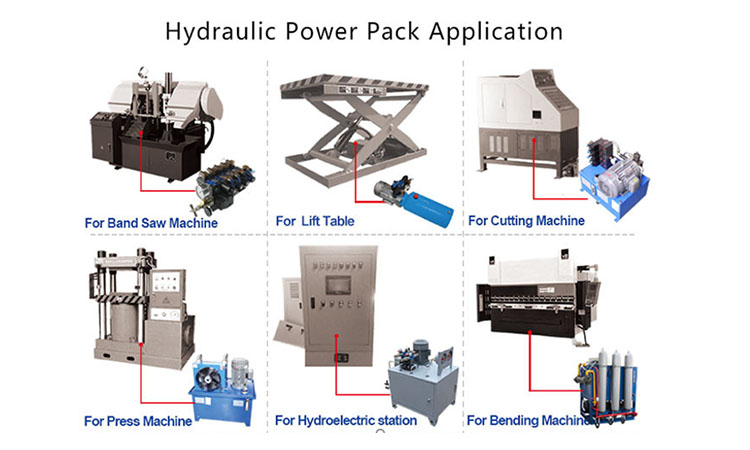

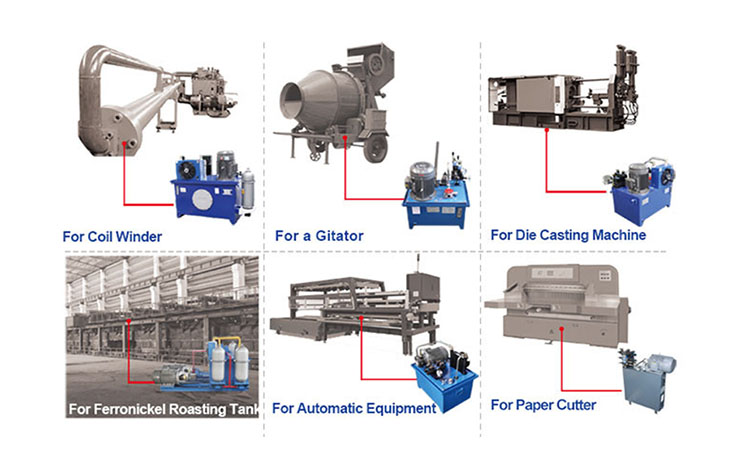

Hydraulic System Application

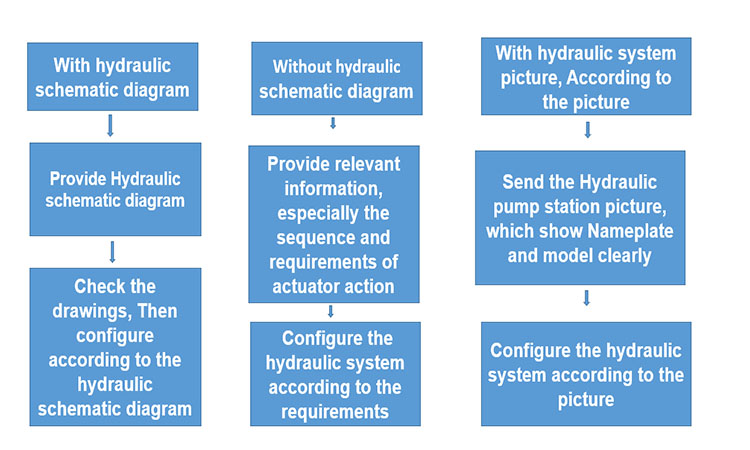

How to order

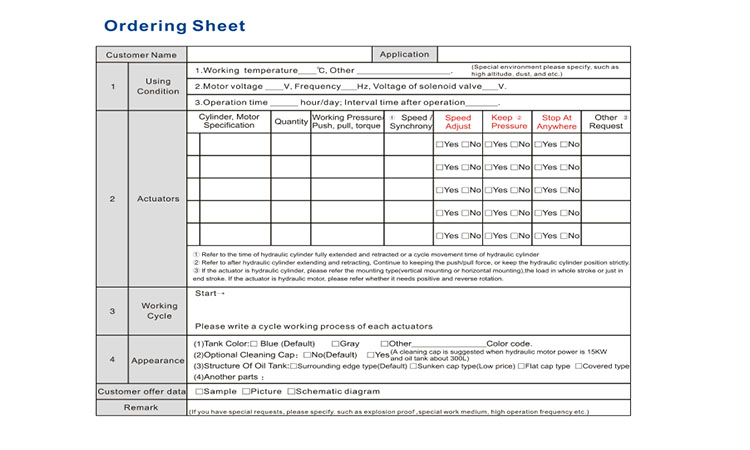

Ordering Sheet

As a Quality Hydraulic System Manufacturer and Supplier in China, Aisoar hydraulics are willing to grow with all partners, and to support partners in every possible way we can.

If you have any question about hydraulic cylinder, please feel free contact us.

Hangzhou Aisoar hydraulic technology Co.,Ltd

Tel: 86-571-87920309

Fax: 86-571-87926329

Mob&Wechat&Whatsapp: +86 13588456446

Email:Jack@ai-soar.com

ES

ES RU

RU